Hydraulic Hybrid Vehicles

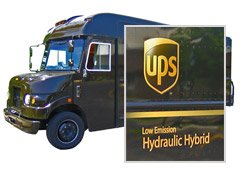

EPA and the United Parcel Service (UPS) have developed a hydraulic hybrid delivery vehicle to explore and demonstrate the environmental benefits of the hydraulic hybrid for urban pick-up and delivery fleets. The demonstration vehicle is a 24,000-pound UPS package car, fitted with an EPA-patented full-series hydraulic hybrid drive integrated into the rear axle. The vehicle competed in the Michelin Challenge Bibendum in China with other advanced technology vehicles and received the top overall ranking among all commercial hybrid vehicles (delivery vehicles and urban buses).

- World's First Full Hydraulic Hybrid in a Delivery Truck

- Hydraulic Hybrid: The Most Efficient Lowest Cost Hybrids

Along with EPA (which worked for over 10 years with a wide variety of private and public sector organizations) and UPS, several other organizations contributed to the development of the hydraulic hybrid vehicle, including Eaton Corporation, International Truck and Engine Corporation, the U.S. Army, Morgan-Olson, the Ford Motor Company, Parker-Hannifin Corporation, Ricardo Inc., Michigan State University, the University of Michigan, and the University of Wisconsin.

Many heavy trucks that operate in urban areas are delivery vehicles, including package trucks, refuse trucks, and buses. These vehicles operate in heavy stop-go traffic and contribute to urban pollution and fuel consumption. A UPS truck is a good representative of the typical urban-based vehicle, making it an ideal pilot for the hydraulic hybrid. The UPS pilot vehicle demonstrates the cost effectiveness of hydraulic hybrid technology which can be applied to all trucks that operate in urban environments as well as highway vehicles.

In laboratory tests, the city fuel economy of the hydraulic hybrid UPS vehicle is 60% to 70% increased miles per gallon compared to a conventional UPS truck. The CO2 emissions of the demonstration UPS vehicle are more than 40% lower than a comparable conventional UPS vehicle. The hydraulic hybrid vehicle also achieves approximately 50% lower hydrocarbon and 60% lower particulate matter in laboratory tests. This prototype vehicle has also demonstrated modest reductions in NOx emissions. Optimized production vehicles are expected to have larger NOx reductions. Hydraulic hybrids are able to capture and reuse 70-80% of the otherwise wasted braking energy.

When commercialized in high volume, EPA estimates that the additional cost of hydraulic hybrid technology has the potential to be about $7,000 for the UPS package car. In today’s dollars, the net lifetime savings of this technology in a typical UPS truck, which is used for 20 years, would be over $50,000. If fuel prices continue to increase faster than inflation, the lifetime savings would be even greater. The current data demonstrates that hydraulic hybrid vehicles have great potential not only for large commercial urban vehicles but also for personal vehicles, especially larger personal vehicles such as large SUVs, pickups, and vans.

By working to commercialize this innovative technology, we can reduce greenhouse gases, reduce US energy consumption, and reduce our dependence on foreign oil. The use of hydraulic hybrid vehicles can also contribute to reduced air pollution which results in a cleaner environment and healthier people.

News Release

- A hybrid vehicle, in addition to its main engine, has a drivetrain that can recover and reuse energy

- A different kind of transmission, one that can recover, store and reuse power hydraulically (rather than electrically)

- An energy storage system

- A hydraulic drive system to convert the stored energy to motive power

- Store energy in hydraulic accumulators

- Use hydraulic pump-motors

- Store energy in batteries and/or ultra-capacitors

- Use electric generator-motors