EPA RCRA ID: MID005356647

On this page:

- Cleanup Status

- Facility Description

- Contaminants at this Facility

- Institutional/Engineer Controls

- Enforcement and Compliance

- Related Information

- Contacts for this Facility

Cleanup Status

Note: The state is the lead agency for managing this facility. For more information about cleanup activities, visit the state’s web page.

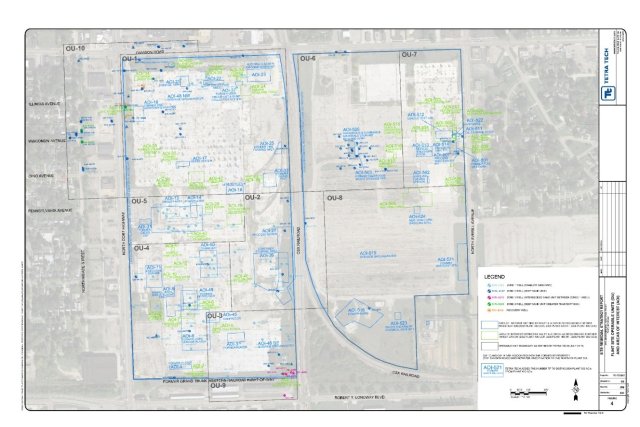

The Trust found areas of interest, or AOIs, at the site, which primarily included features such as milling and machining areas, degreasers, plating operation areas, chemical storage areas, waste accumulation areas, and USTs. AOIs are areas having a known or suspected release of hazardous waste or hazardous constituents that may pose a current or potential threat to human health or the environment. The Trust developed AOIs for Plant 400 and Plant 500 based on previous investigations and historical records. Recent site data generated by the Trust, evaluated alongside the historical data, was used to develop Operational Units, or OUs, for the facility. AOIs with similar chemicals of concern, prior land use, and proximity were grouped together to set up the OUs. The OUs were created to provide manageable areas for investigation, interim measures, and proposed remedies. OU 1 through OU 8 are on the Site, and OU 9 and OU 10 are off the Site. The AOIs and OUs are shown in Figure 1.

EPA is selecting the remedy to address the 10 OUs at the Site. EPA’s proposed remedy for the site’s soil and groundwater impacts includes institutional controls, or ICs, in the form of legally recorded restrictive covenants; monitoring and passive recovery of light non- aqueous phase liquid, or LNAPL, which has similar physical characteristics to oil; soil removal and disposal; underground or “in situ” chemical treatment, including in situ chemical oxidation and in situ chemical reduction; in situ bioremediation; in situ adsorption barrier, or; and monitored natural attenuation. The purpose of the selected remedy will be to protect people currently using the Site, off-site residents, and future industrial and/or commercial workers from harmful health effects caused by potential exposure to contamination.

Cleanup Actions or environmental indicators characterizing the entire facility are shown below. It is not intended as an extensive list of milestones/activities. This listing, and all the data on this page, come from EPA’s RCRAInfo and are refreshed nightly to this page. For this table and the Cleanup Activities Pertaining to a Portion of the Facility table that follows, a blank in the Status column could mean the action either has not occurred or has not been reported in RCRAInfo.

Cleanup Activities Pertaining to the Entire Facility

| Action | Status | Date of Action |

|---|---|---|

| Human Exposure Under Control Human Exposure Under Control(CA725) | ||

| Groundwater Migration Under ControlGroundwater Migration Under Control (CA750) | ||

| Remedy DecisionRemedy Decision (CA400) | ||

| Remedy ConstructionRemedy Construction (CA550) | ||

| Ready for Anticipated Use Ready for Anticipated Use (CA800) | ||

| Performance Standards AttainedPerformance Standards Attained (CA900) | ||

| Corrective Action Process TerminatedCorrective Action Process Terminated (CA999) |

For definitions of the terms used, hover over or click on the term.

Cleanup Activities Pertaining to a Portion of the Facility

| Action | Area Name | Date of Action |

|---|

For definitions of the terms used, hover over or click on the term.

Facility Description

Link to a larger, interactive view of the map.

The former Delphi Flint East Complex included Plant 400 and Plant 500, referred to as the Site. Plant 400, consisting of 70 acres, was the location of a large auto parts plant. The automotive products manufactured at the Plant 400 Property included spark plugs, dashboard components, fuel system components, filter components, and fuel pumps using a variety of lubricating oils, degreasing solvents, paints, and fuels. Plant 500, consisting of 60 acres, was the location of an office building, research center, and parking lot.

The Plant 400 property was first developed in the early 1900s and Plant 500 in the late 1950s. Both plants were owned by General Motors Corporation and were part of the Flint East Manufacturing Complex. In 1999, General Motors conveyed the plants to Delphi Corporation. In 2002, Delphi Corporation transferred ownership of the plants to Delphi Holdings Group. In 2005, Delphi Corporation declared bankruptcy and announced plans to close the Flint East Manufacturing Complex. Manufacturing at the complex ended in early 2006. Plant 400 and Plant 500 buildings were demolished in 2008 and 2009, leaving only concrete slabs, asphalt, and gravel. The DPH Environmental Response Trust, referred to as the Trust, was established on December 9, 2013 as part of the resolution of the DPH Holdings Corporation bankruptcy and the Site was conveyed to the Trust.

The Site is currently vacant except for two leased areas (one on the Plant 400 property and one on the Plant 500 property). The lease agreement allows the tenant, Dort Auto LLC, to store cars and light trucks in the leased areas.

Contaminants at this Facility

Multiple environmental investigations and activities have been performed at the Site beginning in the late 1980s. The investigations and activities were primarily performed to address releases from underground petroleum and solvent storage tanks, the former manufacturing areas, and chemical and waste storage areas. Site investigations have discovered that soil and groundwater at the Site have been impacted by contaminants from gasoline, diesel fuel, hydraulic and cutting oils and solvents. Volatile organic compounds found at the site include trichloroethene, or TCE, carbon tetrachloride, benzene, and toluene. Also present at the site are light non-aqueous phase liquids, or LNAPLs, a class of pollutant that does not readily dissolve in groundwater and is lighter than water. LNAPL at the site is primarily from oils that were used in the manufacturing process.

Over the course of the environmental investigation, soil and groundwater data were collected to determine what the chemicals of concern were, where they were located, and what risks they posed:

Soil, Groundwater & Hydrogeologic Investigations

- 2002-2005: A multi-phase Resource Conservation and Recovery Act, or RCRA, Facility Investigation was performed between 2002 and 2005 for the Plant 400 property. The investigation was performed to determine if hazard waste or constituents had been released that would pose an unacceptable risk to human health or the environment and to characterize the nature and extent of releases. The investigation included soil and groundwater sampling and the data was evaluated to identify environmental conditions warranting further investigation. The results indicated that soil and groundwater impacts were defined and that impacts from soil and groundwater did not pose a significant human health or ecological risk.

- 2006: A soil and groundwater investigation was performed for the Plant 500 property in October 2006 to identify potential releases of hazardous waste, hazardous constituents, hazardous substances and/or petroleum products at the Site. Based on the initial screening of the data collected during the field investigation activities, further evaluation was recommended.

- 2014-2021: Multiple soil, groundwater investigations were performed by the Trust between 2014 and 2021 on both Plant 400 and Plant 500 to obtain additional data required to further characterize the nature and extent of constituents. The results were used to develop the potential remedies described above.

Ecological (Plant and Animal) Investigations

The Site is located outside a metropolitan area in a predominantly industrial and commercial area with residences to the north, east, and west. Asphalt, concrete, and stone cover most of the property. A small portion of the facility is covered by grass, with some poplar trees growing through areas between concrete slabs. No substantial ecological features exist on site or in the immediate vicinity of the facility.

Institutional/engineered controls

Institutional controls, or ICs, will be placed on the Site property. ICs restrict land or resource use at a facility through legal instruments and are distinct from engineered or constructed remedies. ICs preclude or minimize exposures to contamination or protect the integrity of a remedy by limiting land or resource use through means such as rules, regulations, building permit requirements, well-drilling prohibitions and other types of ordinances. For an IC to become part of a remedy, there must be binding documentation such as land-use restrictions in a recorded environmental covenant, local zoning restrictions, or rules restricting private wells.

Groundwater

A city of Flint ordinance prevents the use of groundwater within the city limits without approval of the health department (Part II Code of Ordinances Chapter 46, Division 2. Regulation of Water Sources § 46-25 Use of Spring or Well Water). The groundwater at the Site is not used for drinking water. Furthermore, the city of Flint receives its drinking water from the Great Lakes Water Authority, which does not use local groundwater.

Institutional and Engineering Controls at this Facility

Institutional and Engineering Controls help ensure human exposure and groundwater migration are under control at a cleanup facility. Where control types have been reported by states and EPA in EPA’s RCRAInfo, they are shown below. Not all control types are needed at all facilities, and some facilities do not require any controls. Where there are blanks, the control types may not be needed, may not be in place, or may not be reported in RCRAInfo.

Are Controls in Place at this Facility?

|

Control(s) Type |

Control(s) in Place? |

Areas Subject to Control(s) |

Documents available on-line: |

|

|---|---|---|---|---|

|

Institutional ControlsNon-engineering controls used to restrict land use or land access in order to protect people and the environment from exposure to hazardous substances remaining in the site/or facility. (CA 772) |

Informational DevicesInformational Devices (ID) |

|||

|

Governmental Controls (GC) |

||||

|

Enforcement and Permit Tools (EP) |

||||

| Proprietary ControlsProprietary Controls (PR) | ||||

|

Engineering ControlsEngineering measures designed to minimize the potential for human exposure to contamination by either limiting direct contact with contaminated areas or controlling migration of contaminants. (CA 770) |

Groundwater ControlGroundwater Control (GW) |

|||

|

Non-Groundwater |

||||

For definitions of the terms used, hover over or click on the term.

Enforcement and Compliance at this Facility

EPA’s Office of Enforcement and Compliance Assurance (OECA) provides detailed historical information about enforcement and compliance activities at each RCRA Corrective Action Site in their Enforcement and Compliance Historical Online (ECHO) system.

RCRA Enforcement and Compliance Reports from ECHO

Related Information

For more information about this facility, see these other EPA links:

- RCRA information in EPA’s Envirofacts database

- Information about this facility submitted to EPA under different environmental programs as reported in EPA’s Facility Registry Services

- Alternative Names for this facility as reported by EPA programs in EPA’s Facility Registry Services

- Cleanups in My Community provides an interactive map to see EPA cleanups in context with additional data, and lists for downloading data

- Search RCRA Corrective Action Sites provides a search feature for Corrective Action Sites

Contacts for this Facility

- Colleen Olsberg, Project Coordinator, ([email protected]), 312-353-4686.

- Francisco Arcaute, Public Affairs Specialist, ([email protected]), 312-886-7613.

- Diane Russell, Public Affairs Specialist ([email protected]), 989-395-3493.