Kansas Dairy Ingredients Facility - 2018 P2 Awardee

Hugoton, Kansas

Additional KDI Activities Include:

Activity 1: An environmentally responsible, milk processing business model

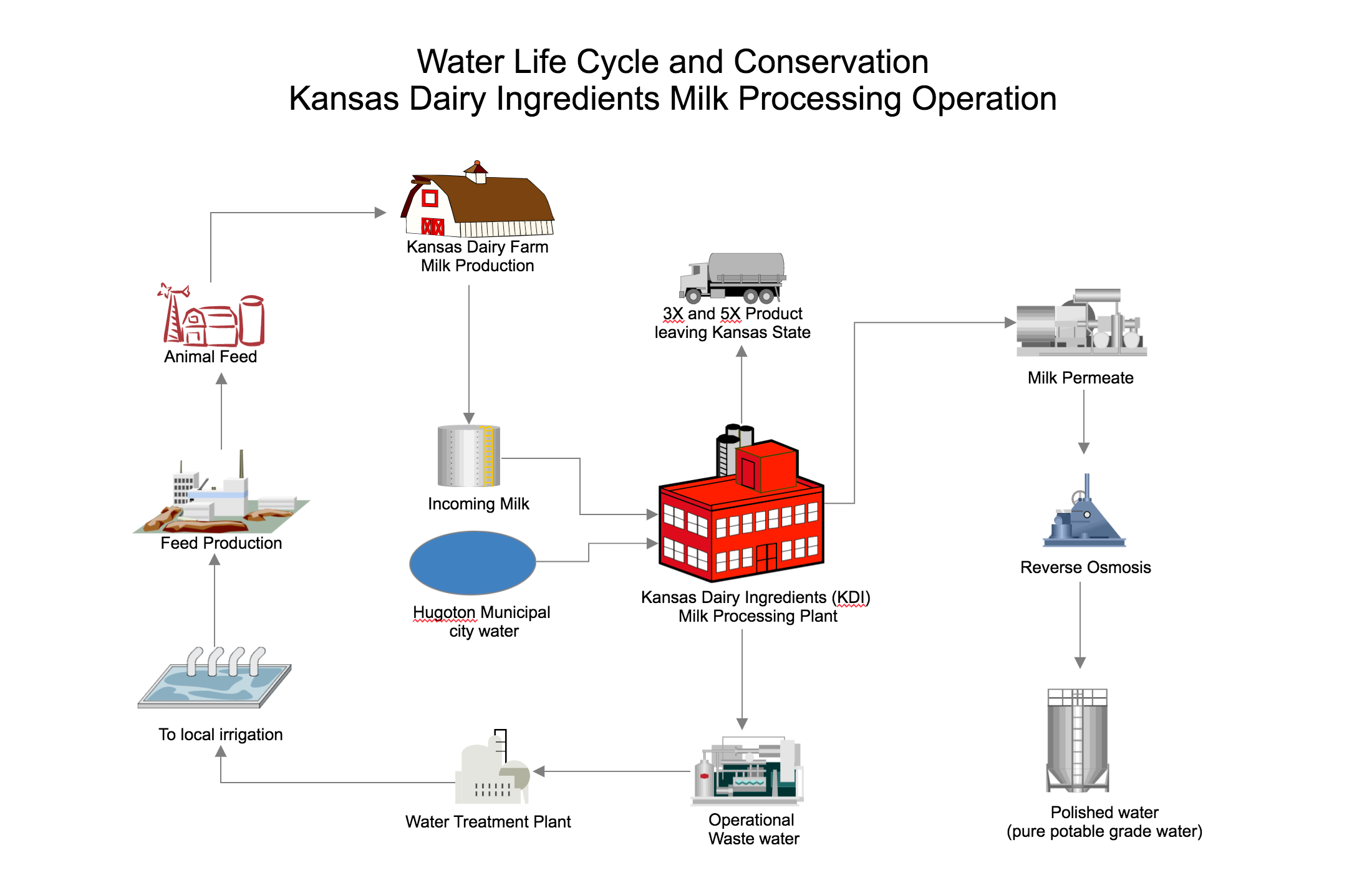

KDI manufactures concentrated milk by filtration, since milk is composed of 87 percent water. Concentration reduces the volume of milk transported, realizing a tremendous logistics and transportation benefit.

-

Reduced operations, logistics, and fuel due to reduction of number of truckloads

- Milk can be transported longer distances economically

- Prevention of pollution by reducing carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) emissions by utilizing fewer trucks to transport the milk to market

Activity 2: Use of filtered water in processing

Water is removed from milk by filtration. Reclaimed water is used in processing, which reduces municipal water procurement and wastewater. Filtered water environmental benefits realized are 41,766,007 gallons/year.

Activity 3: Extended production runs

Twenty hours of continuous production is the industry standard. KDI implemented extended production runs by utilizing innovative processing techniques that reduced wash cycles, cleaning chemicals, water, and electricity use.

Acid - 556 gallons

Activity 4: Local resource water life cycle and conservation

The process at KDI conserves water locally, which benefits both the environment and operations:

Activity 5: Development and implementation of Sustainability Program

KDI’s Sustainability Program is our vision for pollution prevention. The program establishes policy, objectives, organizational structure, data collection and calculation methodology, data evaluation, and monitoring metrics.

Activity 6: Priority to hire from local community

Approximately 75 percent of the employees at KDI are hired from the local community of Hugoton. The average daily roundtrip commute in this region is 60 miles. The location of the plant reduces a lengthy commute for 35 employees, thereby reducing commuting stress and improving employees’ quality of life.

How these activities can be applied to other facilities:

Kansas Dairy Ingredients is a model for other facilities by exemplifying consolidation for bulk transportation and water reuse strategies. Facilities that use bulk transportation of raw materials and finished products can reduce volumes and weight of shipments by concentrating the volume before reaching the processing facility or market. They can also identify means to reduce the weight and volume of the raw material shipment, which helps prevent pollution at many levels.

Filtered processed water can be reused to minimize municipal or groundwater utilization, thereby reducing water pumping, transportation, and wastewater treatment efforts. These collectively reduce energy use that, in turn, prevents pollution.

Industries that use water and bulk transportation can identify pollution prevention opportunities by critically evaluating their operations using aggressive environmental policies. Kansas Dairy Ingredients has learned that management commitment and employee awareness programs are critical and allow identification of pollution prevention opportunities that are otherwise overlooked.