Animal Feeding Operations - Uses of Manure

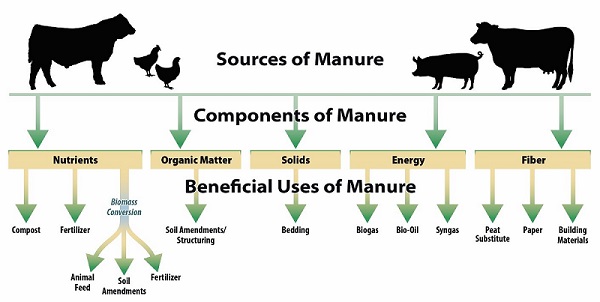

Throughout history, people who raise livestock and poultry have used manure as a fertilizer, soil amendment, energy source, even construction material. Manure contains many useful, recyclable components, including nutrients, organic matter, solids, energy, and fiber. With today’s technology, manure can be used more efficiently and in more ways than ever, which should mitigate many of the environmental impacts that result when manure is treated as a waste.

Nutrients

Farmers, gardeners, landscapers, and others commonly use livestock manure as a fertilizer to provide nutrients needed for crop production. Manure nutrients have real value as fertilizer. Manure’s fertilizer value will increase as the price of commercial fertilizers increase.

Like commercial fertilizer, manure must be managed properly to avoid environmental impacts. Manure has fertilizer value in its raw form; however, processing manure through digestion, composting, or other means can yield materials that are more portable and whose nutrients are more available to plants, more balanced to crop needs, or less prone to environmental losses.

Fresh Manure

Using fresh manure as a fertilizer to raise crops that will be fed back to the livestock, either directly or as a by-product of further processing, is an excellent way to recycle nutrients. Ideally, fresh manure would be used on the farm where the manure is generated or on a neighboring farm, because fresh manure is expensive to haul even short distances.

Livestock manure is commonly land-applied as a semi-solid or liquid. Farmers can incorporate manure into the soil or inject it under the soil surface to reduce the risk of runoff losses and odor problems. Sometimes manure solids are separated from the liquid. Following liquid/solid manure separation, the remaining manure liquids still contain about half of the original nutrients. The solids can be used for bedding or for other uses and the liquids can be land applied to both water and fertilize crops.

Farmers are the most common users of fresh manure for fertilizer, but home gardeners and landscapers also sometimes fertilize with fresh manure.

Compost

Composting livestock manure reduces odors, kills disease-causing agents (pathogens), reduces bulk, and stabilizes the manure for easier handling. A properly constructed and managed manure composting operation can also process mortalities (dead animals) from livestock operations. In some parts of the country, composting operations must be intensively managed to guarantee pathogen-free compost that meets requirements of both health regulations and public perception.

Compost can be applied more evenly and with better control than manure. The nitrogen in compost is not as readily available to plants as the nitrogen in fresh manure, but the availability of phosphorus, potassium and other nutrients from compost is similar to, or higher than, the availability of those nutrients from fresh manure.

Farmers and ranchers can use composted manure at their own operations as fertilizer or bedding. Sales of compost can remove excess nutrients from farms and ranches that cannot use all of their manure nutrients for their own needs.

Compost is less expensive to transport than fresh manure due to its lower moisture content, and more profitable to transport because of its higher market value. This means that compost has more potential for use in areas farther from the farm. Manure compost can be used for many purposes in non-agricultural areas, including site restoration, erosion control, soil remediation, and wetland restoration.

- North Dakota State University Extension's Composting Animal Manures Guide

- Kansas Department of Health and Environment’s Composting at Livestock Facilities

Other Manure Products

Pelletizing compacts fresh manure at high temperature and pressure to convert it into a dry finished product. Pellets are useful as a soil amendment or fertilizer. Because the pellets take up a smaller volume, they can be more easily stored and transported than manure. In some cases, processing can result in a product with a consistent and predictable nutrient content, making it more convenient for crop production and other uses. The pelletizing process is mainly used for poultry litter but could be applied to separated solids from other manures.

Nutrient extraction technologies, or manure nutrient recovery technologies, can remove nutrients from manure for fertilizer products. Nutrient extraction removes elemental nutrients from raw manure, separated liquids, or residuals of anaerobic digestion by chemical precipitation or coagulation. Examples of fertilizer products that can be generated with nutrient extraction systems are ammonium sulfate, calcium phosphate, and magnesium ammonium sulfate (struvite) crystals.

Biomass Conversion

Bioconversion involves growing organisms on manure or manure nutrients and then harvesting them to use as components of animal feed, fertilizer, or soil amendments.

Algae grown on nutrients from dairy wastewater can be harvested to produce a product used in plant fertilizers

and high-protein animal feed supplements. Black soldier fly larvae eat manure, killing disease-causing agents (pathogens) and transferring the manure nutrients to their bodies. The nutrient-rich larvae are a value-added product that can be exported off the farm. High protein feeds made with products like these can be worth up to $500 per ton. The manure left over after the larvae are harvested is useful as a soil amendment or fertilizer similar to compost.

Vermicomposting uses worms to digest manure, creating pathogen-free, nutrient-rich products that can be sold and

exported off the farm. Worms produce nutrient-rich castings. The castings, along with the manure used to grow the worms, are useful as a fertilizer or soil amendment. This vermicompost is said to contain more available plant nutrients than conventional compost. In addition to the revenue from selling the vermicompost, the worms can be sold as fishing bait or processed for supplemental feed for poultry or fish operations.

Organic Matter

Farmers, gardeners, and others use livestock manure as a soil amendment to improve soil quality. In addition to providing nutrients for plant growth, applying fresh or composted livestock manure to cropland improves soil organic matter and tilth (the physical conditions that make a soil suitable for growing crops). Applying livestock manure to cropland increases the amount of organic matter in the soil which improves the soil structure and can increase the soil’s ability to hold water.

Increasing soil organic matter also helps keep carbon in the soil (“carbon sequestration”) and out of the atmosphere where it can form the greenhouse gas carbon dioxide. Manure provides these benefits when it is applied in raw form or when solids are applied after solid-liquid separation, pelletizing, digestion, or composting.

Solids

Some dairy farms use sawdust, wood shavings, straw, sand, or other purchased materials as animal bedding. Bedding can be expensive—on the order of $40 to $50/cow/year. In recent decades, traditional bedding materials like sawdust or sand have become more expensive. Solid material can be recovered from manure (through solid-liquid separation, composting, or anaerobic digestion) and used as bedding, replacing materials purchased from off the farm.

- Use of Dried Manure Solids as Bedding for Dairy Cows (PDF) (9 pp, 487 K, About PDF) - Report by the Cornell Waste Management Institute.

Energy

- Manure Use for Fertilizer and for Energy: Report to Congress - USDA's report states that use of manure for energy production would not detract from the use of manure for fertilizer because the processes used to produce energy leave the manure nutrients as residues to be used elsewhere.

Biogas

Biogas recovered from anaerobic digesters is useful for generating heat or electricity to use on the farm or sell to the local power grid. Biogas production usually uses dairy or swine manure because of their relatively high methane producing potential. However, some digesters in the U.S. use beef manure or poultry litter as feedstocks.

Gas from anaerobic digestion is about 60 to 80 percent methane and has a heating value of 600 – 800 BTU/ft3. (As a comparison, natural gas generally contains more than 85 percent methane and has a heating value of about 950 – 1050 BTU/ft3). Most equipment that uses natural gas, butane, or propane as fuel can be modified to use biogas. This includes boilers, space heaters, and electrical generators.

Because digesters capture methane and other air pollutants, they reduce harmful air emissions from manure and provide superior odor control. Using biogas from digesters also offsets fuel consumption and emissions from non-renewable fossil fuels.

- EPA's AgSTAR program has more information about anaerobic digestion of manure for energy.

Bio-oil

Liquid bio-oil fuels can be produced from manure by thermochemical processes like pyrolysis and gasification. Bioconversion, such as growing algae with manure nutrients, is another process that can produce bio-oil.

Bio-oils are physically different from petroleum-based fuel oil. For example, bio-oils have a lower energy content per gallon and higher acidity than petroleum-based fuel oil. However, tests indicate that bio-oil could be used for applications such as heating or generating electricity.

Commercial experience with biodiesel has been very promising. Biodiesel performs as well as petroleum diesel, while reducing air emissions of particulate matter, carbon monoxide, hydrocarbons and sulfur oxides.

- Pyrolyss Technology: Environmentally friendly solution to nutrient management in the Chesapeake Bay (PDF) (35 pp, 2.9 MB, About PDF) - Virginia Tech reports promising results from its experimental mobile pyrolysis unit for poultry litter treatment.

- California’s Alternative and Renewable Fuel and Vehicle Technology Program projects that commercial-scale biodiesel production from air-dried dairy manure could result in up to 6.8 million gallons of renewable diesel annually, 30 to 50 full-time jobs, and annual greenhouse gas reductions of 851,050 tons equivalent carbon dioxide [CO2e] of methane and 720,666 tons CO2e of nitrogen oxides.

Syngas

Gasification can covert manure (at present mainly poultry litter) into a synthetic gas fuel composed of a mixture of water vapor, tars, hydrogen gas, carbon monoxide, carbon dioxide, nitrogen gas, and hydrocarbon gases. Some of the gas condenses to form a combustible bio-oil. The remaining gas can fuel a variety of power systems including reciprocating engines, gas turbines, and fuel cells.

Fiber

It is possible to produce specialty value-added products from livestock manure for marketing to consumers based on the fiber content of the manure. For the most part, the examples given below are either experimental or done on a boutique scale. Most involve extracting and using the solid fiber from manure.

- Peat moss substitute. Fiber recovered from anaerobic digestion of dairy manure is useful as a plant growth medium. Plant growth trials have shown that, when properly processed, the fiber performs like peat moss for growing container plants.

- Novelty Fiber products. Farmers and other innovators are finding creative ways to make value-added products from fiber recovered from manure.

- Nursery pots, manure-fiber based seed starter pots, made with biodegradable composted cow manure.

- Sculptures made with composted manure and marketed as fertilizing garden art.

- Paper made from processed manure from a variety of animals, including elephants and cows. The dried manure is rinsed in water, leaving the undigested fiber, which is boiled and mixed with other natural fibers to manufacture a variety of paper products.

- Building materials. Recovered manure fiber has been included in fiberboard for building construction.