Missoula Railyard Reduces Costs and Idling Emissions

The Missoula railyard project focuses on reducing air pollution and saving money from reduced fuel consumption by switcher locomotives at the Montana Rail Link (MRL) Railyard in Missoula, Montana during colder months. Installing auxiliary power units (APUs) on eight switcher locomotives, and changing the mandatory idling policy to better fit daily temperature conditions resulted in significant fuel savings.

Overview

The city of Missoula, Montana is located along the Clark Fork River in western Montana and is the second largest metropolitan area in the state. Missoula has average low temperatures below 40 degrees Fahrenheit for eight months out of the year. Missoula County is designated as a carbon monoxide (CO) maintenance area and a PM10 (particulate matter with an aerodynamic diameter less than or equal to a nominal 10 micrometers) moderate nonattainment area based on EPA’s National Ambient Air Quality Standards (NAAQS).

During colder weather months line-haul and switcher locomotives located in the MRL Railyard ran and idled continuously to prevent engine freezing. This continuous idling in the railyard caused elevated air emissions, particularly CO, nitrogen oxides (NOx), particulate matter (PM), and diesel air toxics. Exposure to air pollution associated with emissions from diesel engines can contribute to significant health problems—including premature mortality, increased hospital admissions for heart and lung disease, increased cancer risk, and increased respiratory symptoms – especially for children, the elderly, outdoor workers, and other sensitive populations.2

The Missoula Metropolitan Planning Organization (MPO) and MRL estimated that an average of 30 line-haul locomotives can be idling in the yard at any given time and could produce additional diesel emissions as the locomotives pass through, undergo maintenance, or refuel. The MPO and MRL estimated an annual consumption of approximately 4,800,000 gallons of diesel fuel due to prolonged idling of switcher and line-haul locomotives in the Missoula and other MRL-owned railyards.

Project

MRL considered and implemented several options to reduce emissions from their locomotives including electric plug-ins, automatic engine stop/start (AESS), and APUs prior to the beginning of this project. Ultimately MRL determined the following would be the most cost-effective means going forward to achieve shorter idling periods, lower emissions, and improved health and welfare outcomes.

- Retrofitting their remaining locomotives with APUs, and

- Instituting a temperature-dependent idling policy where idling would only be required when the temperature is below 40 degrees Fahrenheit.

Locomotive APUs are small diesel engines that can be used to prevent prolonged main engine idling when the locomotive is not moving by providing warmth for the main engine and power for crew needs. The APU provides sufficient heat to prevent damage to the main locomotive engine during freezing weather. By reducing the number of hours that the large locomotive engine idles, APU installations can reduce the overall emissions profile of railyards.

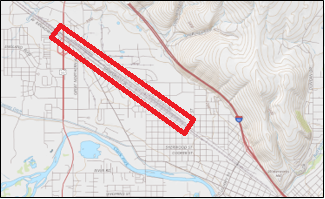

The APU installation portion of this project was partially funded by a 2009 Diesel Emissions Reduction Act (DERA) grant awarded to the MPO that exercises jurisdictional authority over local air quality issues. The grant helped fund

installation of APUs in eight resident switcher locomotives at a mid-sized railyard, located adjacent to downtown Missoula, Montana operated by MRL, a Class II regional railroad. The engines in the eight switcher locomotives that were part of this project are over 50 years old, so they emit diesel emissions that are significantly higher than newer locomotive engines.

The new idling policy, implemented in 2010, which requires idling only when the temperature is below 40 degrees Fahrenheit, replaced the general practice at the railyard of idling main locomotive engines while off-duty for nine months of the year even when the temperature rose above 40 degrees Fahrenheit.

Outcomes

There were 2,618 prolonged idling hours each year per locomotive engine (2,200 hours overnight “must idle” periods and 418 hours reported as occurring during normal switcher duty) before installation of the APUs and implementation of the new idling policy at MRL. The installed APUs and new temperature-dependent idling policy achieved the following idling outcomes.

- On average, it was calculated that the railyard annual APU use rate was 1,773 hours (1,355 average annual temperature-determined overnight must-idle hours, and the 418 annual hours of idling during normal operations) per locomotive.

- The locomotive engines were not running when the APUs were in operation, but were kept warm by the APUs to avoid damage during must-idle hours.

The net idling emission reductions due to the yard idling policy change and APU installation that were done in 2010 are noted below:

- Nitrogen Oxides (NOx) Idling Reductions

- 22.924 short tons for all eight locomotives, a 95 percent reduction annually

- 229.24 short tons for 10-year expected lifetime of APUs

- Particulate Matter 10 (PM10) Idling Reductions

- 0.540 short tons for all eight project locomotives, an 89 percent reduction annually

- 5.400 short tons for 10-year expected lifetime of APUs

- Carbon Monoxide (CO) Idling Reductions

- 1.556 short tons for all eight locomotives, a 60 percent reduction annually

- 15.56 short tons for 10-year expected lifetime of APUs

Costs of the APU units and installation as well as cost savings due to reduced fuel usage are outlined below.

- The cost to purchase and install all the APUs on the eight switchers was $243,993.

- Annual fuels savings averaged $235,964 due to the reduced fuel use of the APUs and the implemented idling policy.

- The APUs and their installation were paid for by cost savings in under two years.

- The expected lifetime of the APU units is 10 years, so the net savings in fuel costs after purchase and installation of the eight APUs over the ten-year period will be approximately $2,115,642.

For more in-depth information on idling hours, emissions calculations and cost savings, see the accompanying document: Methodology for Estimating Emission Reductions and Cost Savings from Missoula Railyard Idle Reduction Policy and Auxiliary Power Unit Installation (PDF) (13 pp, 699 K, February 2019, EPA-420-F-19-010, About PDF).

Lessons Learned

MRL has found the APU installations and changes to the Missoula yard idling policy to be a good program that continues to benefit those across Montana, including Montana Rail Link employees and others who work and live near the railyard. Attention to diligent maintenance and repair of APUs, as well as the training of new locomotive operators in proper APU monitoring and operation were also essential to the success of this idle reduction initiative.

1Tom Danneman, Montana Rail Link Photo Roster (Kalmbach Media Co., April 15, 2013).

2Near Roadway Air Pollution and Health: Frequently Asked Questions (PDF) (August 2014,EPA-420-F-14-044).

3HOTSTART Inc., “APU (Auxiliary Power Unit),”accessed May 15, 2018.