Test and Treat PFAS: EPA SBIR Technologies

Per- and polyfluoroalkyl substances (PFAS) are a group of manufactured chemicals that have been widely used since the 1940s. They have many useful properties, but they can break down very slowly and can build up in animals and the environment over time. Due to their widespread use and environmental persistence, most people in the United States have been exposed to certain PFAS. Most known exposures are relatively low, but some can be high, particularly when people are exposed to a concentrated source over long periods of time. A growing body of scientific evidence shows that exposure at certain levels to specific PFAS can adversely impact human health and other living things. Because of the potential risks to human health and the environment, the U.S. Environmental Protection Agency (EPA) is committed to taking action on PFAS, which includes investing in research, development and innovation to increase understanding of PFAS. EPA’s Small Business Innovation Research (SBIR) program has supported many companies that are developing strategies to detect, assess and treat PFAS in the environment. The wide variety of PFAS and the places they are found mean that many new technologies and innovative ideas are needed—several SBIR-supported companies working to test and treat PFAS are highlighted here.

To determine levels of PFAS contamination in soils and sediments, Accurate Environmental Laboratories developed a passive sampling method that accumulates PFAS from the surrounding environment via diffusion. When the sampler is placed into a soil-water matrix, the PFAS diffuse into its sorbent resin, which can then be removed for analysis. The initial project showed good accumulation for the three PFAS tested, and the sampling device can be manufactured inexpensively. Although further work is needed to increase the precision of the analysis, this technology is less labor-intensive than many others currently in use, and it can provide a better risk characterization method to sample and monitor PFAS at investigatory or remediation sites.

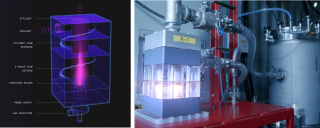

Once PFAS have been identified in a contaminated site, removal and destruction methods unique to that environment are needed. Onvector LLC has developed advanced plasma vortex equipment for the destruction of PFAS contaminants in water. Its plasma vortex reactor stretches a plasma arc to reliably generate a wide variety of oxidizing and reactant agents within a water matrix. The plasma discharge is stable regardless of the conductivity of the liquid and operates at low pressure and temperature, improving overall energy efficiency compared with high pressure and temperature destruction platforms. In testing, Onvector’s reactor destroyed more than 99 percent of two of the most common types of PFAS. Onvector is completing a seed investment round of $2.5 million and pilot testing its technology with the US Air Force.

To prevent further contamination of the environment by PFAS, cost-effective onsite pretreatment technologies are needed for industrial wastewater. OxByEl Technologies, Inc., has developed a low-cost, continuous flow-through method to electrochemically mineralize PFAS in minutes with no secondary waste. OxByEl’s method is more cost-effective than current electrochemical processes, which use expensive electrodes, have long treatment times and low energy efficiencies. With EPA SBIR support, OXbyEL was able to develop a scalable, single-pass reactor that can treat a large volume of water without the need for large tanks or long wait times. Wastewater also contains complex mixtures of organics, pathogens, and inorganics. The OXbyEL technology eliminates these co-contaminants simultaneously with PFAS, replacing multiple treatment steps to save space and reduce treatment cost. Through other SBIR support, OXbyEL developed an energy efficient Electrolyzer architecture with low-cost and durable electrodes for on-site PFAS destruction to prevent PFAS contaminant plumes from reaching drinking water wells. The process safely mineralizes groundwater PFAS in a single step with no degradation by-products. In addition, OXbyEL is preparing to field-test a pilot Electrolyzer mineralizing PFAS and co-contaminants in groundwater at a US Air Force Base.

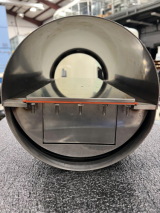

BioLargo, Inc. developed another type of water stream treatment, an aqueous electrostatic concentrator (AEC) that can remove PFAS from water or wastewater, capturing the PFAS on a membrane for further treatment and/or disposal. BioLargo’s technology has been proven to remove more than 99 percent of both long and short chain PFAS from the feed stream in a single pass. Bench-scale studies have proven that BioLargo’s AEC is able to remove both high and low concentrations of PFAS without issue. Further testing had demonstrated that removal to non-detect levels is possible with the technology. Additional testing is underway to validate the technology at greater scales as well as verify its effectiveness when treating landfill leachate. The company has also tested the technology in bench- and pilot-scale studies with water from several sites across the US, including both municipal and industrial customers. Contract work is underway for two full-scale units.

Claros Technologies, Inc., developed a proprietary technology that allows for the total destruction of toxic persistent chemicals, including long, short, and ultrashort per- and poly-fluoroalkyl substances (PFAS), into their natural basic elements and harmless byproducts. The Elemental™ photochemical system achieves over 99% destruction of all PFAS compounds, including ultrashort chains (C1-C3) within 1-3 hours. In addition, energy use and cost studies show the Elemental solution is a low-energy, small-footprint system that operates at room temperature and atmospheric pressure. The process can be used in a batch or continuous mode with low/easy maintenance. The by-products of the process are free fluoride and CO2. The system can be scaled up with low CapEx and energy costs and installed and managed on-site. Claros is working with partners in the wastewater treatment industry to commercialize this system.

Several SBIR-supported companies have researched methods to treat PFAS-contaminated ground water. Most current strategies for PFAS remediation in ground water require that the water be extracted before it can be treated, which is expensive and energy intensive. RemWell, Inc., is working on in situ remediation technology based on recent advances in horizontal wells, which can passively capture and focus flow from a wide upstream zone. RemWell’s reactor is installed within a horizontal well and uses sonolysis to destroy PFAS in the ground water captured by that well. RemWell is developing and testing additional sizes, investigating pretreatments, reviewing the design, and developing a user interface and automated control system.

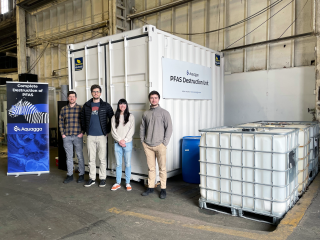

Another SBIR-supported company is Aquagga, Inc., which uses a hydrothermal alkaline treatment (HALT) process to destroy more than 99.99 percent of PFAS in a wide range of liquid matrices. The process also has low energy consumption and scalable processing parameters. After demonstration of the technology and full design of the pilot-scale system, Aquagga is fabricating the pilot-scale system and testing its PFAS destruction performance. This pilot will de-risk use of the technology for PFAS-affected sites and demonstrate its ease of integration with existing remediation practices. Aquagga is working to transition to commercial deployment at active PFAS remediation sites. Aquagga has raised over $750,000 in private investment to-date and has received additional funding through contracts with the Alaska DOT and Defense Advanced Research Projects Agency (DARPA) to advance the scaled-up HALT system to be used for field demos and remediation projects at multiple airports and air force bases.

Cyclopure, Inc., has developed a PFAS treatment train that uses its novel cyclodextrin adsorbent (DEXSORB ®) to remove PFAS from water, regenerates the adsorbent for reuse, concentrates the extracted waste into a solid, and mechanochemically mineralizes the PFAS into nontoxic inorganic salts. Prototype treatment trains were validated during EPA-funded research, which led to field demonstration of the treatment train at a North Carolina drinking water treatment plant. Cyclopure has now deployed DEXSORB in over 15 pilot-scale packed bed filtration systems to remove PFAS in diverse water environments, including groundwater, surface water, wastewater and landfill leachate. The company is in the process of constructing full-scale regeneration and PFAS destruction hubs in Illinois and Michigan to support commercial operations.

EPA’s support for small businesses through these SBIR projects helps extend its PFAS action strategies into many new and innovative areas and advances technology to reduce these contaminants. With this multifaceted approach across the Agency to address the complex challenges posed by PFAS, EPA strengthens its commitment to protecting human health and the environment, improving the planet and preserving its resources for the future.