Advanced Refrigeration Technologies

A majority of the 45,500 retail food establishments in the United States use centralized direct expansion (DX) systems to chill their products. Typically, these refrigeration systems are charged with 3,000 – 4,000 pounds of refrigerant and can leak in excess of 20 percent of their charge each year.

On this page:

- Background Information

- Centralized DX System

- Distributed System

- Secondary Loop System

- Cascade System

- Transcritical Carbon Dioxide (CO2) System

- Self-contained System

Background Information

Following the transition away from chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs) such as HCFC-22 were the most commonly used refrigerants in large retail food refrigeration systems. In the early 1990s, the retail food refrigeration market began to transition to blends consisting entirely or primarily of hydrofluorocarbons (HFCs) such as R-404A, which are potent greenhouse gases. Currently, the most commonly used refrigerants include R-407A and, more recently, HFC/hydrofluoroolefin (HFO) blends such as R-448A and R-449A.

Fortunately, there have been several advancements in refrigeration technology in recent years, which include modifications to centralized DX systems as well as alternatives, that can help food retailers benefit from advanced refrigeration systems (i.e., those that reduce both refrigerant charges and refrigerant emissions). Additionally, the use of flammable refrigerants (e.g., propane) is growing and is expected to continue to grow as standards are updated to allow for increased charge sizes with these refrigerants.

Below is a general description of a centralized DX system as well as an overview of the different advanced refrigeration options.

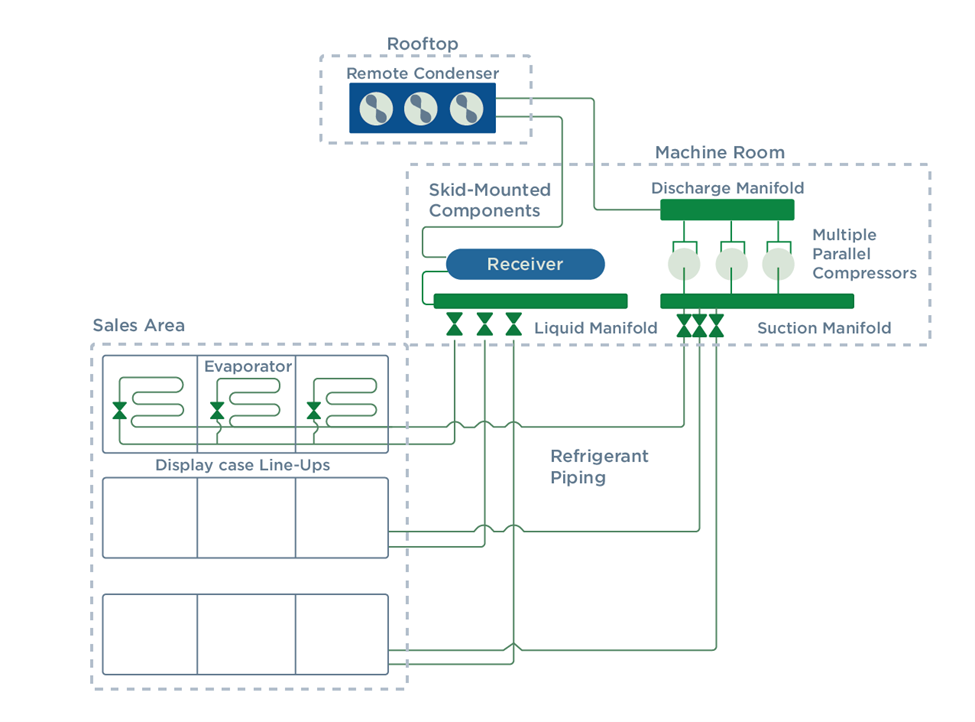

Centralized Direct Expansion System

In a centralized DX system , the compressors are mounted together and share suction and discharge refrigeration lines that run throughout the store, feeding refrigerant to the cases and coolers. The compressors are located in a separate machine room, either in the back of the store or on its roof, to reduce noise and prevent customer access, while the condensers are usually air-cooled and hence are placed outside to reject heat. Centralized DX systems most commonly utilize R-407A, but have begun transitioning to lower global warming potential (GWP) refrigerants, such as HFC/HFO blends (e.g., R-448A, R-449A).

The multiple compressor racks operate at various suction pressures to support display cases operating at different temperatures. The hot gas from the compressors is piped to the condenser and converted to liquid. The liquid refrigerant is then piped to the receiver and distributed to the cases and coolers by the liquid manifold. After cycling through the cases, the refrigerant returns to the suction manifold and the compressors.

Supermarkets tend to have one centralized DX system for low-temperature refrigeration (i.e., storage of frozen foods) and one or two centralized DX systems for medium-temperature refrigeration (i.e., storage of dairy, prepared foods, meat, or refrigerated drinks).

Schematic of a Centralized DX System

Adopted from International Energy Agency (IEA). 2003. "IEA Annex 26: Advanced Supermarket Refrigeration/Heat Recovery Systems, Final Report Volume 1-Executive Summary."

Advanced Centralized DX System

A supermarket may be able to reduce the charge to load ratio and leak rates for a centralized DX system through several approaches, including but not limited to, reducing the distance that refrigerant travels between the rack and display cases, using condensers that employ microchannel coils to reduce the charge size, and utilizing subcooling systems on low-temperature refrigeration to reduce the charge size.

Advanced centralized DX systems achieve a refrigerant charge that is equal to or less than 1.75 lbs. of refrigerant per MBTU/hr. total evaporator heat load and maintain annual leak rates of less than 15 percent.

Distributed System

Unlike centralized direct expansion refrigeration systems, distributed systems use multiple smaller units that are located close to the display cases that they serve. For instance, compressors in a distributed system may be located on the roof above the cases, behind a nearby wall, or even on top of or next to the case in the sales area. The close proximity of the compressors to the cases and coolers allows the system to use considerably less piping and a smaller refrigerant charge than traditional centralized DX systems. This reduction in charge often results in a decrease in total refrigerant emissions. Distributed systems typically use R-407A or R-404A as refrigerants, but are beginning to use HFC/HFO blends (e.g., R-448A, R-449A) more frequently.

Schematic of a Distributed System

Adopted from International Energy Agency (IEA). 2003. "IEA Annex 26: Advanced Supermarket Refrigeration/Heat Recovery Systems, Final Report Volume 1-Executive Summary."

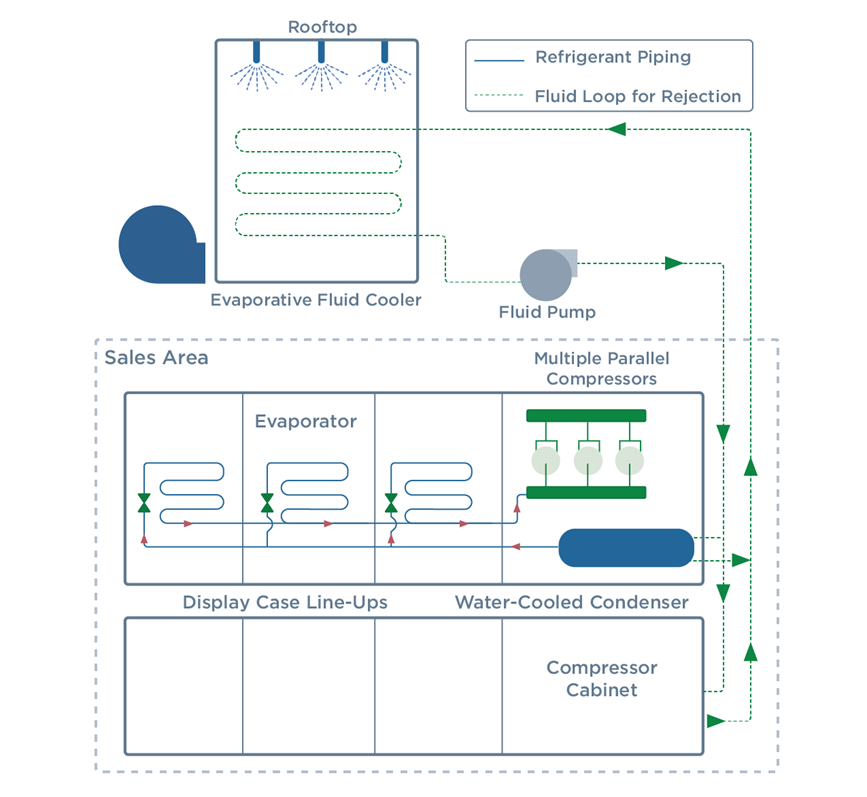

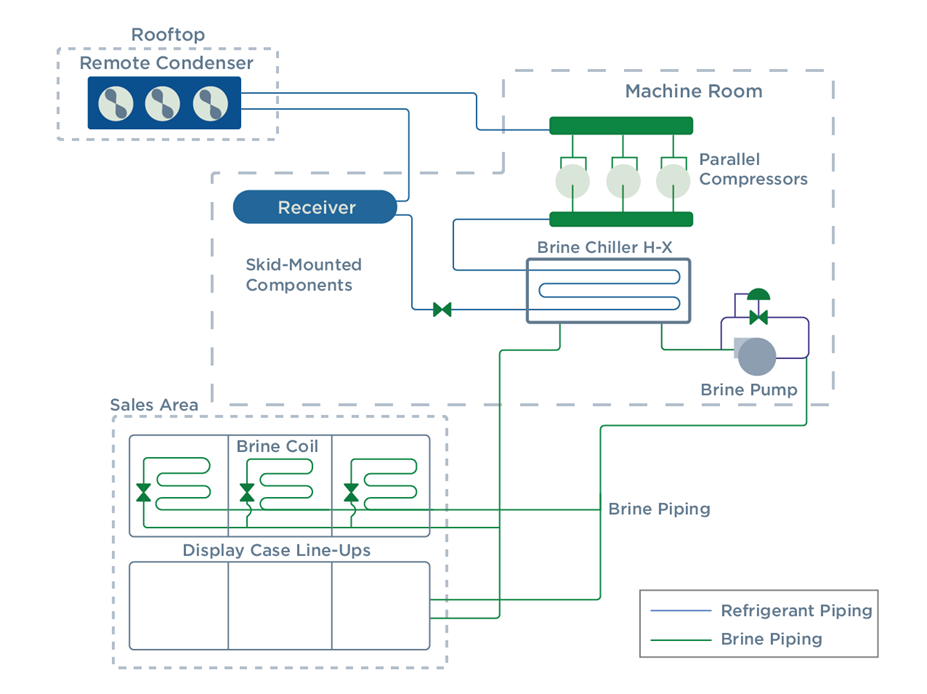

Secondary Loop System

Secondary loop systems use a much smaller refrigerant charge than traditional direct expansion refrigeration systems and hence have significantly lower total refrigerant emissions. In secondary loop systems, two fluids are used: a primary refrigerant and a secondary fluid. The secondary fluid is cooled by the primary refrigerant in the machine room and then pumped throughout the store to remove heat from the display equipment. Primary refrigerants can include ammonia (NH3), R-744 (CO2), hydrocarbons, or HFCs and HFC blends such as R-407A and R-404A. Secondary fluids can include water or glycol. Secondary loop systems typically include two to four chiller systems, depending on the temperatures needed for the display cases.

Schematic of a Secondary Loop System

Adopted from Southern California Edison and Foster-Miller, Inc. 2004. "Investigation of Secondary Loop Supermarket Refrigeration Systems." Report prepared for California Energy Commission, Public Interest Energy Research Program.

Cascade System

Cascade systems consist of two independent refrigeration systems that share a common cascade heat exchanger. Each system of a cascade system uses a different refrigerant that is most suitable for the given temperature range. High temperature systems use high boiling point refrigerants such as R-404A, R-507A, R-134A, propane, butane, and ammonia, whereas low temperature systems use low boiling refrigerants such as R-744 (CO2) and R-508B. The advantages of a cascade system include a reduction in the refrigerant charge and a reduced carbon footprint.

Transcritical CO2 System

Transcritical CO2 refrigeration is a type of refrigeration cycle in which CO2 is the sole refrigerant, evaporating in the subcritical region and rejecting heat at temperatures above the critical point in a gas cooler instead of a condenser. CO2 transcritical systems require specialized controls and components to operate at necessary high pressures to accommodate CO2’s low critical temperature.

Currently, HFOs are most commonly employed in refrigeration systems within HFO/HFC blends and offer lower GWPs than their HFC counterparts. These blends balance reducing GWP with maintaining low flammability and efficiency.

Self-contained System

Self-contained equipment incorporates the condenser and evaporator within the unit itself. These systems are pre-piped prior to installation and are hermetically sealed, resulting in average leak rates less than 1 percent annually. Self-contained systems often use HFCs, low-GWP HFC/HFO blends, or hydrocarbons as refrigerants. The small charge sizes required in self-contained display cases allow supermarkets to comply with current hydrocarbon charge restrictions.