Industrial Radiography

- Workers who use industrial radiography equipment are trained and wear special badges that measure their exposure to radiation.

- Workers can only be exposed to a limited amount of radiation per year.

- The public is not permitted in areas where testing is conducted to protect them from radiation exposure and other construction hazards.

Manufacturers use industrial radiography to check for cracks or flaws in materials. Industrial radiography mostly uses x-ray and gamma radiation to show flaws that cannot be detected by the naked eye. Because x-rays and gamma rays can travel through different types of materials, such as air, soil and water, industrial radiography is useful in inspecting materials without having to move or damage the material itself.

About Industrial Radiography

Manufacturers use industrial radiography to ensure that materials are not damaged before they are used. Just like medical x-rays are used to find breaks or cracks in bones, industrial radiography mostly uses x-rays or gamma rays to take pictures of materials because they can show problems that are not visible to the naked eye. Pictures can also be taken from the inside of an object to make sure that there are no cracks that would be impossible to see from the outside. Radiography is useful because it does not damage or change the item being tested. It can also be used when it is difficult or not practical to access the material being inspected.

For example, industrial radiography is used to test:

- Gas and oil pipelines

- Metal welding

- Boilers

- Vehicle parts

- Aircraft parts

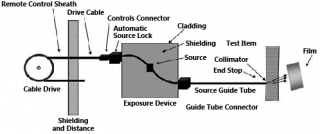

Industrial radiography works by pointing a beam of x-rays or gamma rays at the item being tested. A detector is lined up with the beam on the other side of the item. The detector records x-rays or gamma rays that pass through the material. The thicker the material, the fewer x-rays or gamma rays can pass through. Because the material is thinner where there is a crack or flaw, more rays pass through that area. The detector creates a picture from the rays that pass through, which shows cracks or flaws. The pictures from these cameras are called radiographs. Like photography, industrial radiography has been moving away from film-based radiography and instead moving to digital images.

When you look at a radiograph of welded metal, the welding site shows up bright white because it is thicker than the rest of the pipe material. The welding stops the rays almost completely from passing through, which makes it show up brighter than the rest of the images. The cracks show up as darker areas because the radiation has passed completely through the cracks.

X-ray and gamma ray industrial radiography devices are different and used for different purposes.

Source: National Academy of Sciences (NAS)

- X-ray radiography devices are powered by electricity. When the device is turned off, x-rays are not produced. X-ray radiography generally creates very clear pictures. The devices are large and good for use in factories.

- The gamma rays used in radiography come from radioactive material inside the radiography device. Gamma ray devices do not need electricity. They are smaller than x-ray devices. Their small size makes them useful for checking inside pipes, ships and other small spaces. However, they cannot be turned off like an x-ray device. The radionuclides in the device always produce gamma rays. The only way to block a gamma radiation from a radiography device is to interrupt the beam with heavy metal. The metal will not allow the gamma rays to pass. Workers must be careful to shield the gamma device when it is not in use to protect others from radiation exposure.

What You Can Do

- Obey safety instructions. You are unlikely to be exposed to radiation from industrial radiography equipment because the general public is not permitted near the equipment when testing materials. However, if you are anywhere near these devices, be sure to follow all safety rules.