Best Management Practices

WaterSense at Work is a compilation of water-efficiency best management practices (BMPs) that can help commercial and institutional facilities understand and manage their water use, establish an effective water management program, and identify projects and practices that can reduce facility water use. WaterSense released the first version of the document in 2012 (308 pp, 6 MB) and is updating and releasing new sections as they are completed.

- Commercial & Institutional Facilities Fact Sheet(2 pp, 500 K, About PDF)

Facility owners and managers interested in better understanding, managing, and reducing facility water use should review Sections 1 and 2, which are applicable to all facility types. Sections 3 through 8 address opportunities associated with specific equipment and systems. Section overviews can be found below the table.

Each BMP provides an overview of the technology; tips for operation, maintenance, and user education; options for retrofits and replacements; and calculations for potential water, energy, and dollar savings and payback periods.

|

Section |

Best Management Practices (BMPs) Covered |

Publication Date |

|

November 2023 |

||

|

November 2023 |

||

| 1.3 Education and Outreach (pdf) | November 2023 | |

| 1.4 Codes, Standards, and Voluntary Programs for Water Efficiency (pdf) | November 2023 | |

| 1.5 Water-Energy Nexus (pdf) | November 2023 | |

|

November 2023 |

||

| 2.2 Leak Detection and Repair (pdf) | November 2023 | |

| 2.3 Benchmarking (pdf) |

March 2024 |

|

|

May 2023 |

||

|

May 2023 |

||

|

May 2023 |

||

|

May 2023 |

||

|

May 2023 |

||

|

May 2023 |

||

|

October 2012 |

||

|

May 2023 |

||

|

October 2012 |

||

|

October 2012 |

||

|

October 2012 |

||

|

October 2012 |

||

|

October 2012 |

||

|

October 2012 |

||

|

October 2012 |

||

|

November 2023 |

||

|

November 2023 |

||

|

November 2023 |

||

|

November 2023 |

||

|

October 2012 |

||

|

October 2012 |

||

|

October 2012 |

||

|

October 2012 |

||

|

October 2012 |

||

|

March 2024 |

||

|

March 2024 |

||

|

March 2024 |

||

|

March 2024 |

||

|

March 2024 |

||

| 7.6 Vivarium Washing and Watering Systems (pdf) |

March 2024 |

|

|

March 2024 |

||

|

October 2012 |

Section Overviews

Getting Started With Water Management

Developing a water management plan for a facility will help you understand how and where water is used and identify and prioritize water-saving projects. Effectively educating facility staff, building occupants, employees, and visitors about water use and water management planning goals is key to properly managing and reducing facility water use. Understanding codes, standards, and voluntary programs for water efficiency and the connection between energy and water savings can also help you set facility water reduction goals.

Learn about these topics and more in WaterSense at Work Section 1: Getting Started With Water Management, which covers:

- How commercial and institutional facilities in the United States typically use water and the business case for saving water (included in Section 1.1: Introduction)

- Water management planning

- Education and outreach

- Codes, standards, and voluntary programs for water efficiency

- The water-energy nexus

Monitoring and Education

Actively monitoring water use and quickly identifying and repairing leaks are imperative to facility water management. Review the Getting Started section overview for more information on metering and leaks.

Consult WaterSense at Work Section 2: Water Use Monitoring, which covers these topics:

- Metering and submetering

- Leak detection and repair

- Benchmarking

Sanitary Fixtures and Laundry

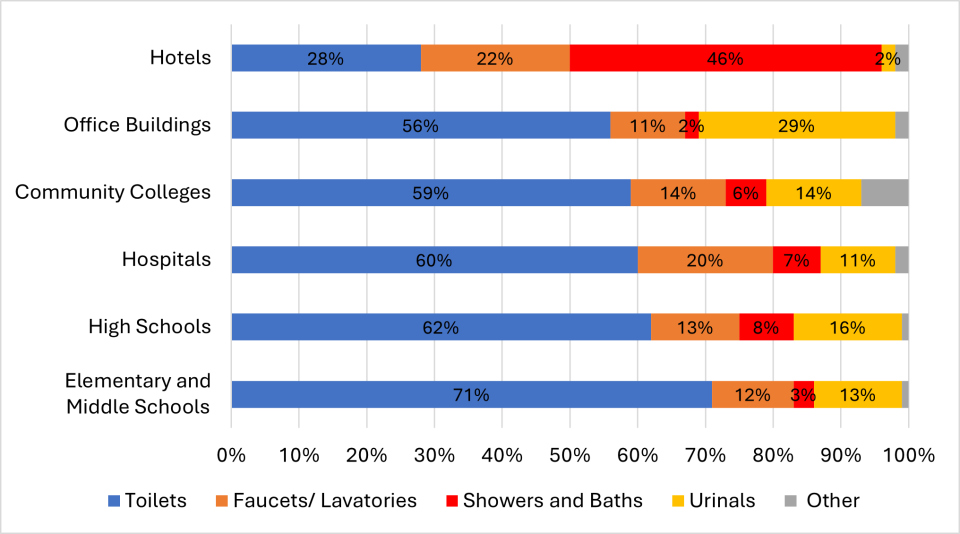

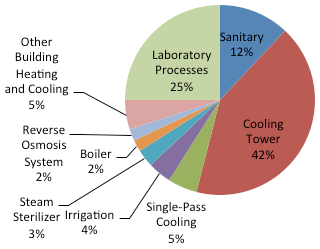

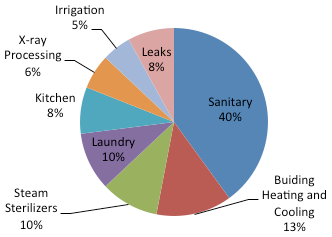

Sanitary fixtures and equipment in restrooms and laundries can account for a significant portion of a facility’s total water use and can provide easy opportunities for water and energy savings, particularly in older buildings with inefficient fixtures and equipment. The figure below shows approximately how much water each type of sanitary fixture uses across various types of facilities.

Percent of Restroom Use by Facility Type

WaterSense at Work Section 3: Sanitary Fixtures and Equipment, provides information on equipment that nearly every type of commercial and institutional facility has including:

- Toilets

- Urinals

- Faucets

- Showerheads

- Laundry equipment

Learn how a hotel in San Antonio saved water and money by retrofitting their bathrooms with water efficient fixtures.

Kitchen Equipment

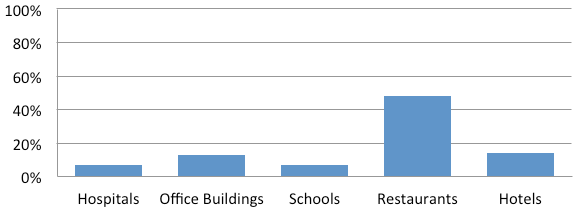

In restaurants, water use in the kitchen can account for nearly 50 percent of the facility's total water use. Kitchen use in other commercial and institutional sectors, including hospitals, offices, schools, and hotels, can account for upwards of 10 to 15 percent of the facility's total water use. The chart below shows the percentage of facility water use that is attributed to kitchens for various commercial facility types.

Percent Water Use Attributed to Commercial Kitchen Equipment

Water use will vary depending upon the scope and scale of the kitchen's operations, with larger kitchens using more water in almost every aspect of their operations when compared to smaller kitchens.

New water-efficient technologies and water-saving practices can significantly reduce commercial kitchen equipment water and energy use. For example, ENERGY STAR® certified dishwashers, ice machines, combination ovens, and steam cookers are at least 10 percent more water efficient and 15 percent more energy efficient than standard models, with some models saving significantly more.

WaterSense at Work Section 4: Commercial Kitchen Equipment provides tips for effectively reducing the water use of:

- Pre-rinse spray valves

- Commercial ice machines

- Combination ovens

- Steam cookers

- Steam kettles

- Wok stoves

- Dipper wells

- Food disposals

- Wash-down sprayers

- Commercial dishwashers

Learn how three restaurants in Chicago; Omaha, Nebraska; and Washington, D.C., saved water and energy by implementing several best management practices.

Outdoor Water Use

Landscape irrigation is the primary source of outdoor water use for most commercial and institutional buildings. Outdoor water use can also encompass water used within water features, pools and spas, and for vehicle washing.

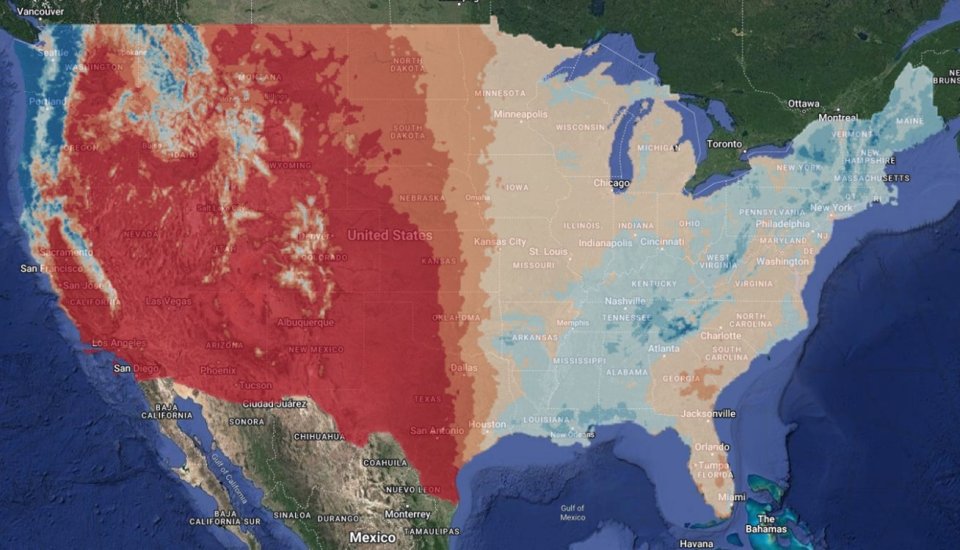

The need for landscape irrigation can vary substantially depending on: the type of facility; size and orientation of the landscape; plant species within the landscape; and the local climate. The amount of water theoretically needed to keep a landscape healthy is the amount of water that is lost due to evapotranspiration. In some places in the United States with more frequent rainfall, precipitation can replace evapotranspiration and eliminate the need for irrigation. However, where precipitation is insufficient to meet the evapotranspiration needs of plants, irrigation water may need to be applied.

The figure below is a map of the United States showing the difference between average precipitation and evapotranspiration in inches per year from 1981 to 2022. Blue areas are areas where precipitation exceeds evapotranspiration. Darker orange and red areas show where annual evapotranspiration more substantially exceeds precipitation and, therefore, where irrigation may be needed in landscaped areas.

Average Annual Potential Water Balance (Precipitation Minus Reference Evapotranspiration in Inches) in the United States from 1981 to 2022

Because outdoor water use can be significant for a facility, using water wisely on the landscape provides a significant water savings opportunity for many facilities.

In addition, many facilities consume significant amounts of water for the operation and maintenance of pools and vehicle washing stations. Proper pool management and reclaiming and reusing water in vehicle washes also provide opportunities for savings.

WaterSense at Work Section 5: Outdoor Water Use provides guidance for effectively reducing the water use associated with:

- Landscaping

- Irrigation

- Commercial pool and spa equipment

- Vehicle washes

Learn how the Granite Park office complex in Plano, Texas, saved nearly 12.5 million gallons of water by increasing the efficiency of the irrigation system.

The U.S. Golf Association (USGA) Golf's Use of Water Resource Center includes information, best management practices, and case studies on how water can be used more efficiently on golf courses. Some of the information may also be useful for facility managers overseeing large landscapes.

Mechanical Systems

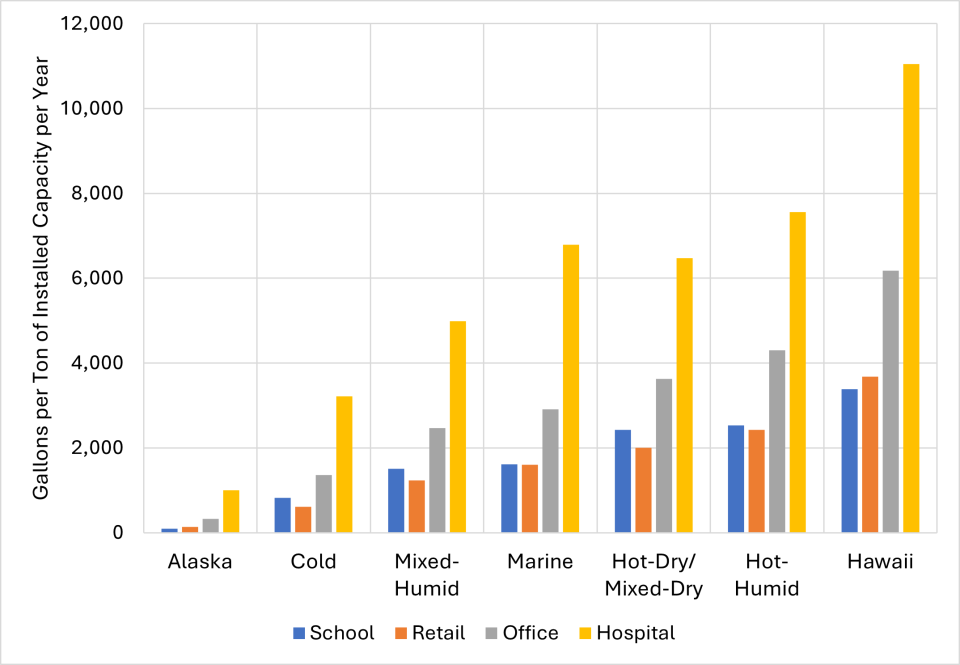

Mechanical systems are used in nearly every type of commercial and institutional facility to provide building heating and cooling. Some also use mechanical systems to cool specific pieces of equipment, such as vacuum pumps, X-ray equipment, and ice machines. Cooling towers tend to be one of the largest mechanical system water uses in facilities that have them. Levels of cooling tower water use vary widely for different commercial facility types depending mostly on the size of the cooling tower and the facility’s local climate. The figure below shows the estimated annual water use required per ton of capacity for a cooling tower to operate at 4.0 cycles of concentration for different building types in various regions and climates.

Estimated Annual Water Use Per Ton of Installed Capacity With a Cooling Tower Operating at 4.0 Cycles of Concentration

Energy and water efficiency measures should be implemented together throughout the facility to decrease the heating and cooling load of the entire system. Increasing the efficiency of the overall systems results in significant reductions in energy and water and cost savings.

To reduce mechanical system water use, facilities should first eliminate single-pass cooling or reuse that water, then evaluate cooling towers, chilled water systems, and other heating systems to maximize efficiency. In some cases, single-pass cooling can be the single largest water user at a facility, using approximately 40 times more water to remove the same heat load than a cooling tower operating at five cycles of concentration. Ensuring that cooling towers and chilled water systems are properly maintained will minimize the amount of cold water needed to remove heat from equipment. Water use can also be optimized in boiler and steam systems by returning steam condensate back into the system.

WaterSense at Work Section 6: Mechanical Systems provides an overview of and guidance for effectively reducing the water use of:

- Single-pass cooling

- Cooling towers

- Chilled water systems

- Boiler and steam systems

Learn more about how the U.S. Environmental Protection Agency's Mid-Continent Ecology Division Laboratory in Duluth, Minnesota, eliminated single-pass cooling and reduced its potable water use by 90 percent.

Laboratory and Medical Equipment

Laboratories and medical facilities have special operations and equipment that can consume a significant amount of water through water purification, sterilization, photographic and X-ray processes, and vacuum systems. As shown below, equipment such as steam sterilizers and reverse osmosis systems can account for 5 percent of a laboratory's total water use. Hospitals can attribute more than 15 percent of their total water use to laboratory and medical equipment, including steam sterilizers and X-ray processing equipment.

Laboratories and medical facilities may face unique challenges because of the high quality of the water required for their equipment to maintain purification and health and safety standards. These standards can limit the types of technologies that can be utilized, but many improvement opportunities still exist. Water efficiency alone will not be a driver in the choice of technologies or processes in these facilities, but it should be a consideration after other requirements have been met.

WaterSense at Work Section 7: Laboratory and Medical Equipment provides an overview of and guidance for effectively reducing the water use of:

- Water purification

- Vacuum pumps

- Steam sterilizers

- Glassware washers

- Fume hood filtration and wash-down systems

- Vivarium washing and watering systems

- Photographic and X-ray equipment

In addition to WaterSense at Work, WaterSense, in coordination with the International Institute for Sustainable Laboratories (I2SL), updated a best practices guide (40 pp, 8 MB, About PDF) on water efficiency for laboratories.

Learn how Providence St. Peter Hospital in Olympia, Washington, saved 31 million gallons of water by installing water-efficient laboratory and medical equipment and implementing many additional best management practices described in WaterSense at Work.

Alternative Water Sources

Facilities can further reduce potable water use by taking advantage of onsite alternative water sources, in which water discharge from one application or process is captured, treated, and utilized in another application. These onsite alternative water sources can vary greatly in quality and must be carefully matched with an appropriate end use.

Potential onsite alternative water sources include:

- Rainwater/stormwater

- Foundation drain water

- Treated gray water

- Condensate from air handler equipment

- Filter and membrane (e.g., reverse osmosis system) reject water

- Cooling equipment blowdown

Although discharge from single-pass cooling systems can be a suitable onsite alternative water source, facility managers should first consider eliminating single-pass cooling, as described in Section 6.2: Single-Pass Cooling. If elimination is not possible, then consider reuse of the discharge water for another purpose.

General considerations for reuse of onsite sources of water include the quality constraints of the source and the potential types of treatment that may be needed to meet the quality needs of the proposed end use. Every situation is different, but many resources provide guidance on typical considerations.

WaterSense at Work Section 8: Onsite Alternative Water Sources describes potential uses of onsite alternative water including:

- Irrigation

- Cooling tower make-up water

- Toilet and urinal flushing

- Make-up water for decorative ponds, fountains, and waterfalls

- Processes or other uses not requiring potable water

- Fume hood scrubbers

Learn more about how the University of Texas at Austin used onsite alternative water sources to reduce its potable water use by more than 33 percent.