Inadvertent PCBs

- Basic Information

- Regulatory Context

- Enforcement

- iPCBs in Products and the Environment

- EPA Research and Pollution Prevention

Basic Information

In the United States, polychlorinated biphenyls (PCBs) were commercially manufactured from 1929 until production was banned in 1979 by the Toxic Substances Control Act (TSCA). However, EPA’s regulations implementing TSCA for PCBs allow some inadvertent generation of PCBs to occur in excluded manufacturing processes, as defined in title 40 of the Code of Federal Regulations (CFR) section 761.3.

Specifically, the PCB regulations allow inadvertently generated PCBs (iPCBs) at defined concentrations, under certain conditions, and with requirements to report to EPA and maintain certain records.

EPA, through the Office of Research and Development, has been working to better understand the concentrations of iPCBs in products, potential emission and migration of iPCBs out of products, and potential exposure pathways to users or other potentially exposed populations.

Regulatory Context

The PCB regulations exclude some manufacturing processes from regulation. Refer to 40 CFR section 761.1(f). Excluded manufacturing processes are defined in 40 CFR section 761.3, which sets limits on the concentration of iPCBs in products. The concentration of iPCBs in products must have an annual average of <25 parts per million (ppm), with a 50 ppm maximum, except that the concentration must be <5 ppm in the components of detergent bars. 40 CFR section 761.3 also includes restrictions on discharges of iPCBs to ambient air or water, and disposal of process wastes.

iPCBs are defined in the definition of PCBs at 40 CFR section 761.3 as the total PCBs calculated following division of the quantity of monochlorinated biphenyls by 50 and dichlorinated biphenyls by 5. Under this formula, monochlorinated and dichlorinated biphenyls essentially receive discounts when calculating the total PCB concentration. Example: Product testing identifies PCB-11 (a dichlorinated biphenyl) as the only detected PCB in a product at a concentration of 250 ppm. The total concentration of PCBs in the product is calculated after dividing the concentration of PCB-11 by 5. Therefore, the total concentration of PCBs in the product is 250/5 = 50 ppm PCB-11.

Under 40 CFR section 761.1(f), manufacturers, importers, processors, distributors, and users of iPCBs are subject to the reporting and recordkeeping requirements of 40 CFR Part 761, Subpart J, as applicable. EPA has received 77 reports from facilities generating or importing iPCBs from 1994-2015 for the following classes of products:

| Chemical or Process | Number of Reports |

|---|---|

| Pigments and Dyes | 53 |

| GE Silicones | 8 |

| Vinyl Chloride Production | 3 |

| Unique | 6 |

| Unknown | 7 |

| Total | 77 |

Enforcement

The PCB regulations exclude only certain concentrations of iPCBs from TSCA’s ban, subject to reporting and recordkeeping requirements. Manufacturing or importing iPCBs at more than allowed concentrations and/or failing to report or keep records may be a violation of the PCB regulations and result in an enforcement action. In 2014, Titanium Metals Corporation (TIMET) agreed to pay a record $13.75 million civil penalty and perform an extensive investigation and cleanup stemming primarily from the unauthorized manufacture and disposal of PCBs at its manufacturing facility in Henderson, Nevada. TIMET, which processes titanium from rutile ore, was alleged to have unlawfully manufactured PCBs as a by-product of its titanium manufacturing process, without an exclusion from TSCA’s ban. The penalty was the largest ever imposed for violations of TSCA at a single facility.

iPCBs in Products and the Environment

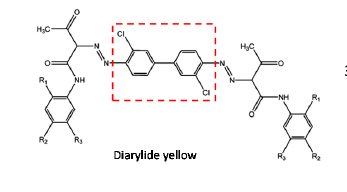

Of the processes generating iPCBs reported to EPA, pigment and dye manufacturing is the most common. As described in the PCB section of America’s Children and the Environment, Third Edition (pdf), inadvertent PCBs have been found in pigments used in paints, inks, textiles, paper, cosmetics, leather, and other materials. The PCB congener PCB-11 is a known component of the diarylide yellow pigment molecule.

The concentrations of iPCBs found in products are generally lower than the Food and Drug Administration's tolerances for PCBs in food and food packaging. The FDA recognizes PCBs as an unavoidable, environmental contaminant and set temporary food tolerances for PCBs ranging from 0.2 to 1.5 ppm, and a tolerance of 10 ppm in paper packaging in direct contact with food. Refer to 21 CFR 109.30(a).

PCBs are bioaccumulative, and low concentrations released to the environment may be magnified in the food web. For example, PCBs bioaccumulate in fish and other aquatic organisms to concentrations tens of thousands of times higher than the concentration in the water – refer to the bioconcentration factor discussion and derivation for PCBs on Page C-12 of the Ambient Water Quality Criteria for PCBs (pdf). Because PCBs are so bioaccumulative, the national recommended water quality criterion for PCBs is set very low, at 0.000064 µg/L. Concentrations below this level are not expected to cause adverse effects to human health.

EPA Research and Pollution Prevention

EPA, through the Office of Research and Development, has been working to better understand the concentrations of iPCBs in products, potential emission and migration of iPCBs out of products, and potential exposure pathways to users or other potentially exposed populations. Results of our first round of product tests are now available.

EPA’s PCB Program and Pollution Prevention (P2) Program have been collaborating (pdf) to identify potential ways to reduce or eliminate iPCBs in products through innovative strategies and technologies. As a result, EPA’s Small Business Innovation Research (SBIR) Program included cleaner manufacturing of coloration techniques in the 2020-2021 solicitation. The SBIR solicitation supports eligible small businesses in the development and commercialization of innovative environmental technologies.