How Does Anaerobic Digestion Work?

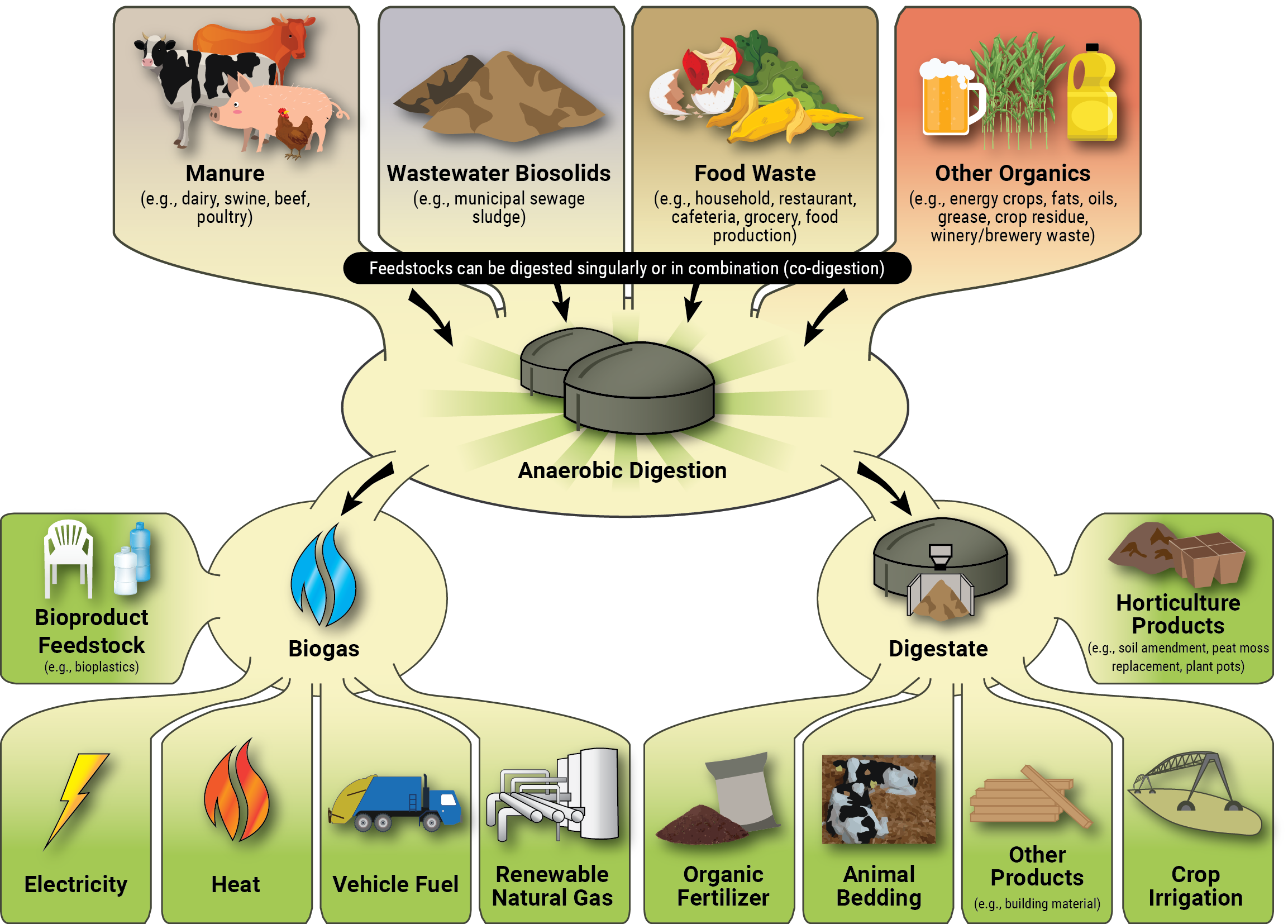

Anaerobic digestion is a process through which bacteria break down organic matter—such as animal manure, wastewater biosolids, and food wastes—in the absence of oxygen. Anaerobic digestion for biogas production takes place in a sealed vessel called a reactor, which is designed and constructed in various shapes and sizes specific to the site and feedstock conditions (learn more about AD system design and technology). These reactors contain complex microbial communities that break down (or digest) the waste and produce resultant biogas and digestate (the solid and liquid material end-products of the AD process) which is discharged from the digester.

Multiple organic materials can be combined in one digester, a practice called co-digestion. Co-digested materials include manure; food waste (i.e., processing, distribution and consumer generated materials); energy crops; crop residues; and fats, oils, and greases (FOG) from restaurant grease traps, and many other sources. Co-digestion can increase biogas production from low-yielding or difficult-to-digest organic waste.

The following figure illustrates the flow of feedstocks through the AD system to produce biogas and digestate.

Anaerobic Digester Outputs

Anaerobic digestion produces two valuable outputs: biogas and digestate.

Biogas

Biogas is composed of methane (CH4), which is the primary component of natural gas, at a relatively high percentage (50 to 75 percent), carbon dioxide (CO2), hydrogen sulfide (H2S), water vapor, and trace amounts of other gases. The energy in biogas can be used like natural gas to provide heat, generate electricity, and power cooling systems, among other uses. Biogas can also be purified by removing the inert or low-value constituents (CO2, water, H2S, etc.) to generate renewable natural gas (RNG). This can be sold and injected into the natural gas distribution system, compressed and used as vehicle fuel, or processed further to generate alternative transportation fuel, energy products, or other advanced biochemicals and bioproducts.

Digestate

Digestate is the residual material left after the digestion process. It is composed of liquid and solid portions. These are often separated and handled independently, as each have value that can be realized with varying degrees of post processing.

With appropriate treatment, both the solid and liquid portions of digestate can be used in many beneficial applications, such as animal bedding (solids), nutrient-rich fertilizer (liquids and solids), a foundation material for bio-based products (e.g., bioplastics), organic-rich compost (solids), and/or simply as soil amendment (solids), the latter of which may include the farm spreading the digestate on the field as fertilizer. Digestate products can be a source of revenue or cost savings, and are often pursued to increase the financial and net-environmental benefit of an AD/biogas project.

Learn More

- Benefits of anaerobic digestion. Presents the many benefits of AD compared to traditional manure management systems.

- AD system design and technology. Describes the elements of a biogas and digestate recovery system.

- AgSTAR Project Development Handbook. Compilation of the latest knowledge in the industry on best practices for AD/ biogas systems. Contains information about AD applications and processes, benefits, challenges, feedstocks, products, economic and financial factors, and more.

- Planning AD Projects. Provides useful information to help plan an AD project, including:

- AgSTAR Project Profiles. Filter, sort, and search for project profiles and case studies of successful AD/biogas systems.

- Livestock Anaerobic Digester Database. Lists and provides key information on all anaerobic digester projects on livestock farms in the United States.

- Anaerobic Digester/Biogas System Operator Guidebook. Provides on-farm AD/biogas system operators with information and guidance that can be used to help successfully operate and maintain AD/biogas systems.