Project Profile: AA Dairy

Key Features

Highlights

- Anaerobic digestion system in operation for nearly 25 years

- Dairy sells compost as soil amendment to help offset digester costs and decrease phosphorous application rate to cropland

- Benefits include removal of odor, increased capacity for farm, and reduction of operating costs

Overview

“We want to stay on the cutting edge of the dairy industry, utilizing new technologies and innovations to increase efficiency of milk production.”

– Bob Aman, AA Dairy

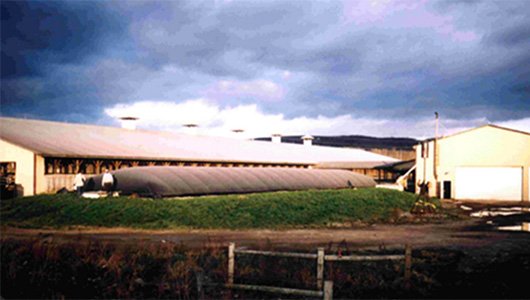

Before commissioning its anaerobic digester in 1998, AA Dairy faced odor issues with manure storage and land application. With plans to expand its herd, AA Dairy needed a way to control odors more economically and manage manure more effectively.

By installing a plug flow digester, the farm not only increased its capacity and reduced odor, but also created revenue streams from electricity generation and the sale of its “Fields of Dreams” compost.

About the Digester

Designed to handle a capacity of 1,000 cows, the 112-foot digester receives approximately 11,000 gallons of manure each day from about 600 cows. The manure, scraped from the free stall barn, contains newspaper, sawdust, and shavings that are used for bedding. A flexible cover captures the biogas produced, which is collected, filtered, and pressurized before fueling a 130-kW engine-generator set that produces enough power to operate the farm. AA Dairy sells excess electricity to the local utility.

AA Dairy uses a screw press separator to remove coarse fiber from the digester effluent. The dairy then composts the fiber and sells it as a soil amendment called “Fields of Dreams,” which has a dry matter content between 20 and 30 percent and a pH of about eight. The farm sells various quantities of compost, from 20-pound bags to truckloads. Sale of the compost has helped to offset the capital cost of the digester and reduce the rate of phosphorous application to the farm’s cropland.

Benefits

AA Dairy advances sustainability in the following ways:

- Protects human health by reducing pathogens in manure through the anaerobic digestion process

- Improves quality of life in the community by reducing odor on local farms

- Reduces methane emissions from livestock manure

- Decreases phosphorus application to land

- Offsets the use of fossil fuels in electricity generation

- Generates revenue from the sale of compost as a soil amendment

- Reduces operating costs by producing renewable energy and using it on site

System Design Properties

| Property | Value |

|---|---|

| Feedstock Processed | Dairy cow manure |

| Digester type | Horizontal plug flow |

| Population Feeding Digester | 600 dairy cows |

| Baseline System | Storage tank, pond, or pit |

| System Designer and Developer | RCM International, LLC (now Martin Construction Resource, LLC) |

| Biogas Generation | 42,868 ft3/day |

| Receiving Utility | New York State Electric & Gas |

| Biogas Uses | Cogeneration |

| Genset Output | 130 kW |

System Financing

AA Dairy received a grant through the Tioga County Soil and Water Conservation District to help fund the project, but the award did not cover the entire cost of the system. The combined economic value of stabilized solids and electricity generation allowed AA Dairy to recover its capital investment and continues to generate income.

Want to learn more?

Review a case study by Cornell University’s Manure Management Program, at https://ecommons.cornell.edu/bitstream/handle/1813/65738/DES_AA_Case_Study.pdf?sequence=2&isAllowed=y.

For more information about Martin Construction Resource, visit https://martinenergygroup.com/digesters/.

Pursuant to 5 CFR § 2635.702(c)(2), names are displayed here as the result of recognition for achievement given under an agency program of recognition for accomplishment in support of the agency’s mission. Any reference to a specific company or commercial product or service by trade name, trademark, manufacturer, company, or otherwise does not constitute or imply the endorsement or recommendation of EPA. Reviewed December 2021.