Project Profile: Bar-Way Farm

Highlights

- Innovative business model featuring a third-party firm to develop and operate the digester

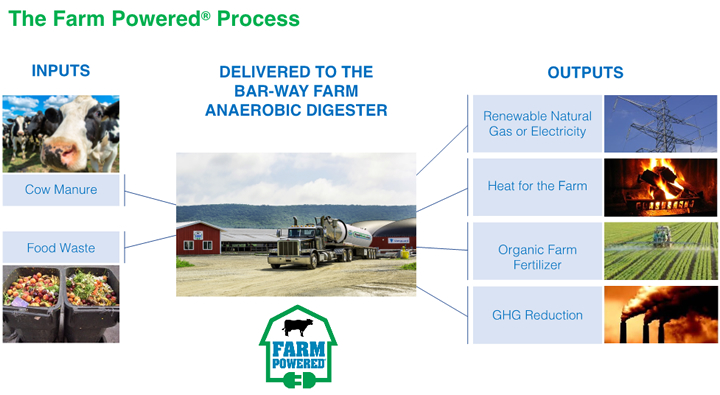

- Manure from the farm and food waste from nearby food manufacturers and businesses are fed into the anaerobic digester to produce electricity, heat, and hot water

- First digester in the United States to utilize a hydrolyzer

- End products from the digester are used as bedding for the farm’s cows and as a fertilizer on the farm’s hay fields

View a printer-friendly version of this profile

Pursuant to 5 CFR § 2635.702(c)(2), names are displayed here as the result of recognition for achievement given under an agency program of recognition for accomplishment in support of the agency’s mission. Any reference to a specific company or commercial product or service by trade name, trademark, manufacturer, company, or otherwise does not constitute or imply the endorsement or recommendation of EPA.

Founded in 1919, Bar-Way Farm, Inc. is a fifth-generation, 600-acre dairy farm owned and operated by Steven Melnik and his son, Peter. More than 250 dairy cows produce 1,700 gallons of milk a day. In addition to the dairy operation, Bar-Way Farm grows straw, hay, butternut squash, pumpkins, and garlic. Bar-Way Farm is committed to making the highest quality milk in the most sustainable environment possible, while also keeping the family farm business profitable. They accomplish these goals by using an anaerobic digester at the farm through a partnership with Vanguard Renewables. The digester, constructed in 2016, annually processes 9,125 tons of manure and 36,500 tons of local food waste into energy, heat, and fertilizer.

Producing Energy from Manure and Food Waste

In 2014, Massachusetts banned the disposal of food waste by operations that generate more than one ton of food waste per week. The food waste is required to be diverted to compost, conversion, recycle, or reuse facilities. Anaerobic digesters are one option for food waste generators to divert and recycle their food waste. The Bar-Way Farm digester helps with implementation of Massachusetts’ commercial food waste ban by accepting organic material from supermarkets, restaurants, institutions, and food manufacturers.

"Our Farm Powered organics recycling and farm-based anaerobic digester program is the first to vertically integrate the organics feedstock chain and farms to solve food waste challenges, generate renewable energy, and sustain farms."

– John Hanselman, Vanguard Renewables

The Farm Powered® Vanguard Bar-Way Farm digester is the first digester in the United States to include a hydrolyzer. The hydrolyzer is a tank that aggregates and homogenizes the feedstock before it is pumped into the anaerobic digester. In the hydrolyzer, particles in the feedstock begin to be broken down and oxygen is removed. The hydrolyzed feedstock is then pumped to the anaerobic digester, optimizing system utilization. Every day the digester accepts 25 tons of manure and 100 tons of food waste. Following the digester process, solids are separated and used to provide bedding for farm animals.

Farm Powered Organics to Energy System at Bar-Way Farm

Benefits

Bar-Way Farm advances sustainability in the following ways:

- Reduces odor from cow manure allowing the farm to be a better neighbor

- Protects human health by reducing pathogens in manure through the anaerobic digestion process

- Sustains the family farm for future generations

- Provides educational opportunities for area schools, colleges, and universities

- Reduces the use of petrochemical fertilizers, by producing an organic fertilizer for farm use

- Reduces greenhouse gas emissions and produces enough energy to power 900 homes

- Protects local water resources by reducing nutrient run-off and pathogens

- Annually diverts 36,500 tons of food waste from landfills

- Reduces farm operating costs by producing electricity, heat and hot water for the farm

- Diversifies revenue streams in the farm’s budget; reducing reliance on and price shocks associated with milk revenue

- Energy generated by the digester is uploaded to the grid

- Produces highly-potent fertilizer that increases crop yields and reduces chemical fertilizer use

- Digestate solids are used as animal bedding

About the Digester

Vanguard Renewables’ Bar-Way Farm anaerobic digester was designed by CHFour Biogas. It consists of a 100,000-gallon hydrolyzer tank that begins the process of anaerobic digestion at 105 degrees Fahrenheit. Every 20 minutes, material is pumped into a 700,000-gallon tank. The digester tank is set 12 feet below-grade and extends an additional 12 feet above ground. Inside the tank, there are two mixers, which push waste down into the center of the tank, preventing sediment accumulation and buildup. The tank is topped by a pair of insulated rubber domes that inflate when methane gas is produced as the manure and food waste undergoes anaerobic digestion. Operation of the anaerobic digester is controlled and monitored by a computer system.

Photo credit: Vanguard Renewables

Photo credit: Vanguard Renewables

"It really is a way to make a dairy farm in the Northeast sustainable, especially in Massachusetts, where we have good access to food waste, and we have a lot more acres than cow manure."

– Peter Melnick, Bar-Way Farm

About 100 tons of organic waste per day arrives on trucks. Food waste for the anaerobic digester is sourced from manufacturers and local businesses. The food waste slurry is placed into the hydrolyzer tank where it stays for four to five days before being pumped into the digester tank where it is mixed with manure to undergo anaerobic digestion. The digester generates methane gas to fuel a 1-megawatt electricity generator and generates approximately 1.62 million BTU per hour of heat that is used both by the facility and by the farm. Vanguard Renewables uploads the energy to the Eversource grid. Additionally, approximately 26,000 gallons of liquid effluent is generated daily providing a high value, odor-free fertilizer that is used on the farm’s crops.

Funding assistance for this digester project came from several sources, including a $335,000 grant from the USDA’s Natural Resources Conservation Service and a $400,000 grant from the Massachusetts Clean Energy Center.

System Design Properties

| Property | Value |

|---|---|

| Feedstock Processed | Manure and Food Waste |

| Annual Digester Input | 9,125 tons of manure and 36,500 tons of food waste |

| Digester Type | Complete Mix |

| Population Feeding Digester | 250 Cows |

| Baseline System | Storage Tank or Pond or Pit |

| System Designer and Developer | Vanguard Renewables / CH4 Biogas |

| Generator Capacity | 7,700 MWh/year |

| Biogas Generation | 409,538 scf/d |

| Receiving Utility | Eversource |

| Biogas Uses | Electricity, Heat, Hot Water |

Recognition

Vanguard’s Bar-Way Farm project has received awards and recognition:

- Vanguard was named the “2018 Organics Recycler of the Year” from the National Waste and Recycling Association.

- “2018 Hospitality Award” (pdf) (300 KB) from the American Biogas Council.

Want to learn more?

Visit Vanguard Renewable’s website for information about its partnership with Bar-Way Farm and the Farm Powered anaerobic digester program.

Learn about the Vanguard’s Bar-Way Farm third-party business model by viewing AgSTAR’s webinar, Innovative Business Models for Anaerobic Digestion Projects.

Review an article published by Greenfield Recorder about Bar-Way Farm’s anaerobic digester project.

Read an article published by the Community Involved in Sustaining Agriculture (CISA) featuring the anaerobic digester at Bar-Way Farm.