Project Profile: Noblehurst Farms

Highlights

- Feedstock includes manure from the farm and approximately 500 tons of food waste per month from local universities, schools, restaurants, and Wegmans Food Markets

- Renewable energy generated to power the farm and nearby creamery

- Nutrient recovery produces high-quality liquid fertilizer for use on the farm

View a printer-friendly version of this profile

Pursuant to 5 CFR § 2635.702(c)(2), names are displayed here as the result of recognition for achievement given under an agency program of recognition for accomplishment in support of the agency’s mission. Any reference to a specific company or commercial product or service by trade name, trademark, manufacturer, company, or otherwise does not constitute or imply the endorsement or recommendation of EPA.

"Digesters are great for the environment and great for power reliability. The sun doesn’t always shine and the wind doesn’t always blow, but we can keep this digester and program going day and night."

– Chris Noble, Noblehurst Farms

Established in 1960 in Linwood, New York, Noblehurst Farms Inc. is a seventh generation multi-family farm with an eye for sustainability and environmental stewardship. The family-run business includes:

- Noblehurst Farms, an 1,800-cow dairy and more than 2,500 acres of land where corn, alfalfa, and wheat are grown;

- Craigs Station Creamery, a milk processing facility;

- Noblehurst Green Energy, which produces electricity; and

- Natural Upcycling, a food-scrap collection business.

Clean renewable energy is produced by the farm’s anaerobic digester, which uses manure from the farm’s dairy cows as well as food waste collected from local grocery stores, restaurants, consumer food companies, universities, and schools. The family’s enduring commitment to preserving the land and consistent focus on long-range planning and profitability have led them to establish innovative partnerships.

Utilizing Food Waste and Generating Power

The digester at Noblehurst Green Energy, which is next to the Noblehurst Farms dairy complex, uses food waste and scraps to increase their biogas yield and boost electricity generation. In March 2014, Noblehurst founded the company Natural Upcycling to collect source-separated organics. Food waste and scraps are collected from local educational institutions (Rochester Institute of Technology and Hobart and William Smith Colleges), restaurants (Chipotle and Gimme! Coffee), schools, a local creamery processing plant, consumer food manufacturing companies (Rich’s and WhiteWave Foods), and more than 30 Wegmans Food Markets stores. Since then, Natural Upcycling has become a premier food scraps and organics recycling collection company.

At Wegmans Food Markets, food scraps and food items that cannot be donated--such as coffee grounds, fruit and vegetable peelings, and damaged produce--are placed into collection totes. Wegmans employees wheel the totes out daily to a loading dock. Natural Upcycling collects the waste using specialized trucks that empty the totes and then sanitize the totes using a built-in power wash system. Once full, the trucks head to the anaerobic digester at Noblehurst Green Energy and deposit the food scraps on a storage pad.

"We truly value our relationship with Natural Upcycling, as it allows us to get closer to our goal of zero waste. The food scraps collection process is easier, safer, and more efficient for our people, and it’s the right thing to do for the environment."

– Jason Wadsworth, Wegmans Food Markets

Upcycle Process

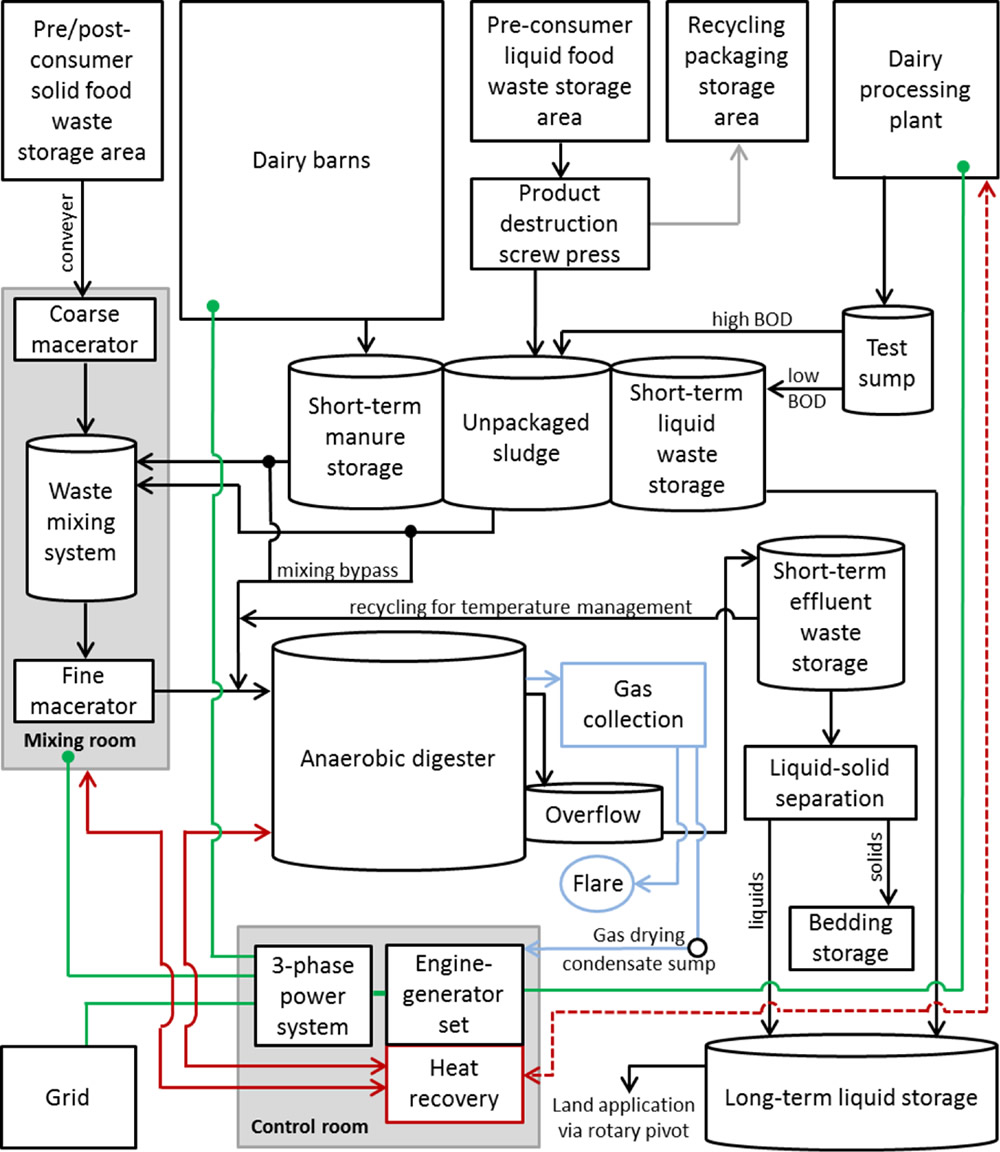

The “upcycle” process creates value from food wastes by converting them into energy. As illustrated in the diagram below, Natural Upcycling accepts a variety of organic wastes from customers, including wastes from:

- Seafood, beef, pork, and poultry products;

- fruits and vegetables;

- dairy and egg products;

- bread, wheat, rice, pasta, and coffee products;

- leaves, bushes, grasses, and weeds; and

- floral and tree trimmings.

These wastes, which are provided by grocery stores, consumer food manufacturers, universities, schools, and restaurants, are collected by Natural Upcycling and delivered to the Noblehurst digester.

Benefits

Noblehurst Farms advances sustainability in the following ways:

- Innovative and entrepreneurial partnerships are creating rural economic growth in New York and inspiring others to find creative solutions

- Raises awareness of food waste recycling and educates people about turning waste into usable energy

- Reduces pathogens in digested manure, protecting human health

- Diverts approximately 500 tons of organic waste per month from landfills

- Avoids 409 tons of carbon dioxide per month, equivalent to 1,046 cars taken off the road

- Use of manured-derived fertilizer reduces dependence on petrochemical fertilizers, which are made from non-renewable sources

- Protects local water resources by reducing nutrient run-off and destroying pathogens

- Reduces operating costs at the farm by producing energy and generating heat and hot water

- Use of the digester saves the farm $100,000 annually in energy costs

- Generates enough renewable energy to power all buildings and machines on the farm as well as a nearby creamery

- Manure treatment and nutrient application complies with manure management regulations, saving additional investment

About the Digester

Construction of a new anaerobic digester began in 2014 to replace the system built in 2001. The anaerobic digester, designed by EnviTec-Biogas USA and operated by affiliate Noblehurst Green Energy, features a 1,336,710-gallon tank. The digester is fed by three waste streams:

- Manure from 1,750 dairy cows from the Noblehurst Farms dairy operations,

- Food waste and scraps collected by Natural Upcycling, and

- Whey and process wastewater piped in from the nearby Craigs Station Creamery milk plant.

Waste from all three waste streams is fed into the automated mixing system according to mass-based ratios that consist of 65 percent manure and 35 percent food and milk processing waste. The mixture is then fed through a macerator and pumped to the anaerobic digester. The anaerobic digester is designed to process 425,000 pounds of influent on a daily basis. Solid and liquid effluent are separated. The solids are used as animal bedding at the farm, and liquid effluent is stored and applied to the land during the growing season.

Combining the Waste Streams

- Manure from Noblehurst Farms is scraped from the barn into a below-grade channel that flows to a 28,000-gallon collection pit. Liquid effluent from the anaerobic digester is mixed into the pit to create a slurry that can be pumped to the anaerobic digester’s mixing room.

- Food waste and scraps are stored on a concrete pad and are loaded onto a conveyer that brings the material to a macerator located in the mixing room.

- Pre-consumer food waste is processed using a screw press and pumped to a pre-digestion storage tank.

- Whey and wastewater from the nearby milk plant that are characterized by a high biochemical oxygen demand (BOD) are transferred to a pre-digestion storage tank.

- Low BOD wastewater is stored for reuse on crop land.

The waste streams are co-digested within the anaerobic digester, producing biogas that is captured and used to generate electricity, heat, and hot water. Hydrogen sulfide is scrubbed from the biogas within the anaerobic digester by injecting ambient air into the headspace of the digester. After hydrogen sulfide abatement, the biogas cools as it is pumped to a combustion engine. Condensate from the cooled gas is collected using a sump. The biogas fuels a 500-kilowatt (kW) generator that produces electricity that is net metered and is enough to power Noblehurst Farms and the nearby Craigs Station Creamery milk plant. Heat is also captured and used to heat the digester and associated rooms, as well as to heat water at the milk processing plant.

System Design Properties

| Property | Value |

|---|---|

| Digester type | Complete Mix |

| Population Feeding Digester | 1,750 Dairy |

| Baseline System | Storage Tank or Pond or Pit |

| System Designer | EnviTec Biogas |

| Biogas Use | Electricity, Heat, and Hot Water |

| Biogas Generation | 432,000 ft3/day |

| Generating Capacity | 440 kW |

| Receiving Utility | National Grid |

System Financing

| Property | Value |

|---|---|

| Total Capital Cost | $3.5 million |

| New York State Energy Research and Development Authority (NYSERDA) PON 2684 Anaerobic Digester Gas-to-Electricity Program | $1.25 million |

| United States Department of Agriculture (USDA) Rural Energy for American Program (REAP) funding | $500,000 |

| National Grid’s Agribusiness Productivity Program | $50,000 |

Recognition

Noblehurst Farms has received awards and recognition for its sustainable and innovative manure management practices:

-

-

Want to learn more?

- For more information about Noblehurst Farms, visit its website at http://www.linwoodag.com/affiliates/noblehurst-farms/.

- Learn more about the technical details of the project by reading Cornell University’s 2016 case study.

- Review a Democrat & Chronicle Passport to Innovation article about Noblehurst Farms.

- Check out a Farm Journal Agweb article about Noblehurst Farms and Christopher Noble.