Trends

CDR Trend Summary

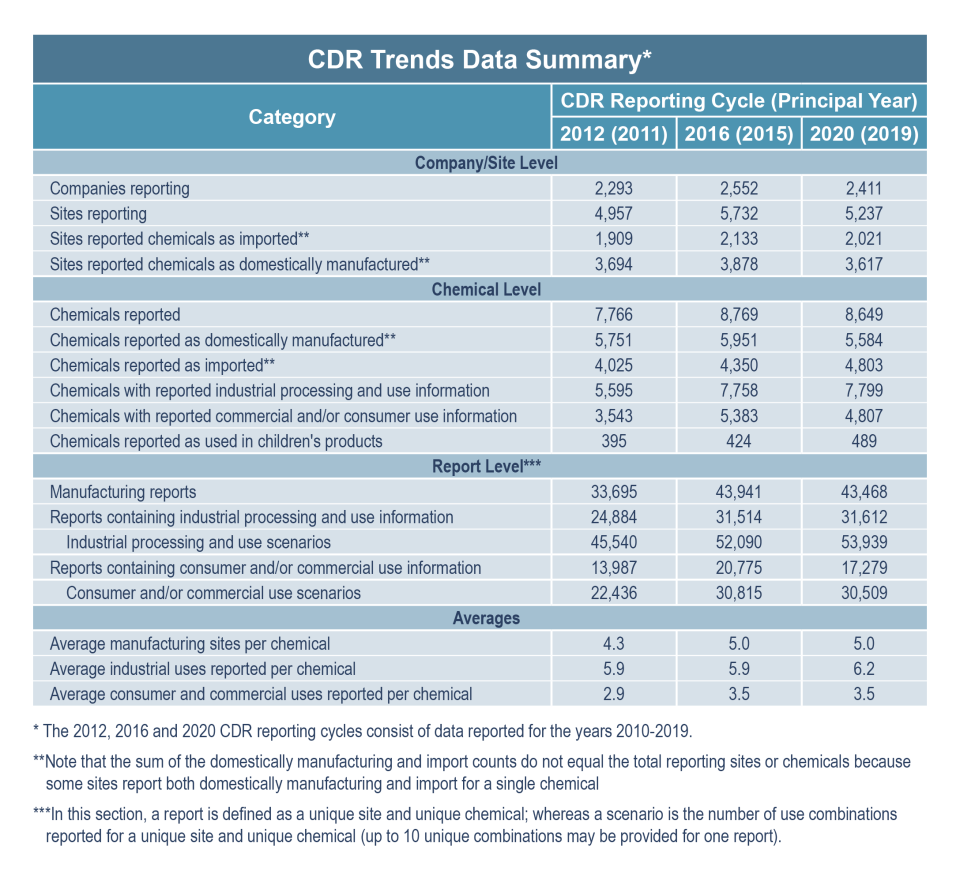

While there have been some changes to required reporting elements over the past 10 years, CDR data can nonetheless be analyzed across the past three reporting cycles to identify trends. The following table shows the trends in company/site level, chemical level, and report level counts for the principal years of the past three CDR reporting cycles (2011, 2015 and 2019). Prior years for each reporting cycle (2010, 2012-2014, and 2016-2018) only specify total production volumes while the principal reporting years (2011, 2015, and 2019) specify additional manufacturing details and processing and use information.

» View larger image

- Overall: There was an increase in the counts across all levels of CDR reporting (company/site counts, chemical counts, and report counts) between the 2012 and 2016 CDR reporting cycles. Between the 2016 and 2020 CDR reporting cycles, the counts stayed about the same, with some having decreased slightly while others increased slightly.

- Manufacturing: Between the 2016 and 2020 CDR reporting cycles, the number of chemicals reported as imported increased by 10% (453 chemicals) while the number of chemicals domestically manufactured decreased by 6% (367 chemicals).

- Consumer/Commercial use: Over the past three reporting cycles, the percent of chemicals and manufacturing reports providing consumer/commercial information averaged at 54% and 43%, respectively.

- Children's products: The number of chemicals reported as used in children's products increased by 24% (94 chemicals) between the 2012 and 2020 CDR reporting cycles. However, consider that there was also an 11% increase (883 chemicals) in all chemicals reported to CDR from the 2012 to 2020 reporting cycles.1

- Industrial processing & use: The percent of manufacturing reports with industrial information has stayed relatively consistent over the past three reporting cycles at about 73%. However, from 2012 to 2020 the percent of chemicals reporting industrial processing and use information increased from 72% to 90%. Industrial uses per chemical increased from an average of 5.9 for the 2016 CDR reporting cycle to 6.2 for the 2020 CDR reporting cycle.

CDR Production Volume Trends

Total production volume (PV) information is available for all 10 years (2010-2019). Sites are only required, however, to report the production volumes associated with domestic manufacturing and import for the principal years (2011, 2015, and 2019). The chart below shows the annual production volumes, along with a trend line of the number of sites that reported production volumes greater than zero. The default view shows the production volume trend for All Chemicals. Use the toggle to view the trend for TSCA Risk Evaluation Chemicals.

Note: Number of sites in this chart differs from the total number of sites for each reporting cycle presented in the 'CDR Trends Data Summary' because the chart provides number of sites reporting a production volume greater than zero for that year.

The spike in production volume in 2015 was mostly due to two sites that reported large domestic manufacturing volumes (Shell Oil Company and Big Spring Refinery reported a total of 9.62 trillion pounds). Excluding the two sites, the total production volume (sum of domestic manufacturing and import volumes) decreased by 0.55 trillion pounds (5%) from 2011 to 2015. These volumes seem to be especially large for the 2015 principal year, since the PV for Shell Oil Company decreased by 99% in 2019. Big Spring Refinery—now Delek US Holdings, Inc.—claimed their 2019 volumes as confidential so a comparison cannot be provided. Overall, the total production volume decreased by 2.16 trillion pounds (23%) from 2011 to 2019.

Note: CDR reporters report domestic manufacture and import production volumes for the principal reporting years (2011, 2015, 2019) and one combined production volume for prior years (2010, 2012-2014, and 2016-2018).

The chart shows the production volume trend for TSCA Risk Evaluation Chemicals, which consist of: the “First Ten Chemicals” that have undergone risk evaluation by EPA’s OPPT since 2016, the “20 High-Priority Chemical Substances”, and the three Manufacturer-Requested Risk Evaluation chemicals (see total TCSA Risk Evaluation Chemical list of 33 by chemical name and 37 by CASRN). Of the total 37 TSCA Risk Evaluation Chemicals by CASRN, 33 chemicals were reported in the 2020 reporting cycle, and 34 chemicals were reported in both the 2012 and 2016 reporting cycles. The figure above illustrates that the number of sites that manufactured and/or imported TSCA Risk Evaluation Chemicals has increased by 40% (62 sites), while the manufactured and imported volumes have generally remained consistent over the past 10 years.

PFAS Production Volume Trends

Per- and polyfluoroalkyl substances—commonly referred to as PFAS are widely used in different products. As a class, PFAS tend to break down very slowly and persist in the environment. EPA identified 219 chemicals across all three reporting cycles that conform to OPPT’s current structural definition for designating a chemical as a PFAS: 180 were reported for the 2020 reporting cycle, 176 were reported for the 2016 CDR reporting cycle, and 109 were reported for the 2012 reporting cycle.2 The figure below shows the production volume for all CDR sites reporting PFAS over the past three reporting cycles.

Comparing the PFAS data reported for years 2010 and 2019, the number of reporting sites increased by 53 percent (18 sites), while the PFAS production volume decreased by 13 percent (133 million pounds). Comparing only principal reporting years 2011, 2015 and 2019, the PFAS domestic manufacturing volume: decreased by 256 million pounds from 2011 to 2015; but increased by 160 million pounds from 2015 to 2019.

There was an increase in: the number of reports for PFAS; the number of PFAS reported on; and the production volume used for the electrical and electronic products category. The PFAS used in electrical or electronic products increased from reporting cycle 2016 to 2020 by eight reports, five chemicals, and 524% in use production volume. The use production volume refers to the consumer/commercial use production volume percentage for a particular use (in this case electrical or electronic products) multiplied by the total reported production volume at the manufacturing (including import) site.

1Sites provide use information to the extent it is known or reasonably ascertainable by them. Some sites may have over or under reported uses of chemicals; these include chemicals used in children's products. EPA is reviewing the CDR use information. For more information, see CDR's frequently asked questions.

2Although the number of PFAS reported for each successive reporting cycle increased, this observation does not directly correlate to an increase in PFAS production or use in commerce. For instance, several PFAS were reported for the 2012 CDR reporting cycle that were not reported for the 2020 reporting cycle. In some cases, a PFAS reported for the first time in the 2020 cycle could have been introduced into commerce during the 2020 CDR reporting cycle.